Tight Tolerance Machining Solutions from Top Suppliers and Factories for Precision Parts

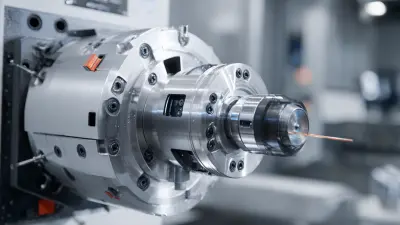

In the realm of Tight Tolerance Machining, precision is paramount. I specialize in providing high-quality machining solutions designed for factories and manufacturers who require exceptional accuracy. With extensive experience, I recognize the importance of precise dimensions and superior surface finishes in your products. My focus on utilizing advanced techniques and cutting-edge equipment ensures every component is crafted to meet your specific requirements. At Kansd Precision Industry Co., Ltd., we prioritize quality and reliability, working alongside you to supply machined parts that improve your production processes. My commitment to excellence guarantees seamless integration, minimized waste, and expedited turnaround times. Together, we can enhance your manufacturing capabilities with premier machining solutions tailored to drive your business success, whether you operate a small workshop or a large factory.

How To Select Tight Tolerance Machining Outperforms the Competition For the Current Year

In today’s competitive landscape, selecting a machining partner with precision capabilities is critical for success. Tight Tolerance Machining refers to the manufacture of components with minimal variations, often within a few micrometers. This process is essential for industries where precision is a non-negotiable requirement, such as aerospace, automotive, and medical devices. When sourcing a machining provider, global purchasers should consider several key factors to ensure they select a partner who can consistently meet their rigorous specifications. Firstly, the machinery utilized by the manufacturer plays a pivotal role in achieving tight tolerances. Advanced CNC machines, lathes, and milling machines should be part of the production lineup, as these tools provide the precision necessary for complex and intricate designs. Additionally, the presence of quality assurance instruments like Coordinate Measuring Machines (CMM) and 2D image measuring systems is vital. These technologies allow for rigorous inspection processes, ensuring that parts not only meet but exceed industry standards. Lastly, the expertise of the workforce is indispensable in maintaining tight tolerances. Skilled technicians who understand the nuances of precision manufacturing are capable of troubleshooting and optimizing production processes. Overall, selecting a machining provider that combines advanced technology, consistent quality control, and skilled craftsmanship will significantly enhance your competitive edge in the market. In a global economy where precision means everything, making the right choice in your manufacturing partner is essential for thriving in your industry.

How To Select Tight Tolerance Machining Outperforms the Competition For the Current Year

| Machining Technology | Tolerance Level (µm) | Material Type | Average Lead Time (Days) | Cost per Unit ($) |

|---|---|---|---|---|

| CNC Milling | 5 | Aluminum | 10 | 20 |

| Wire EDM | 3 | Stainless Steel | 15 | 45 |

| CNC Turning | 7 | Titanium | 12 | 30 |

| Laser Cutting | 4 | Carbon Steel | 8 | 25 |

| Grinding | 2 | Brass | 14 | 60 |

How To Find The Best Tight Tolerance Machining Industry Giant Service

D

Daniel Thompson

Very high-quality merchandise. The after-sales service was impeccable with staff who had a deep understanding of the product.

05 June 2025

N

Noah Thomas

This product has proven to be both reliable and high-quality. The support from the staff really enhanced my experience.

10 May 2025

S

Scarlett Hernandez

What a wonderful product! The quality is top-tier, and the after-sales service team was attentive and knowledgeable.

28 June 2025

Z

Zoe Campbell

Fantastic product! The quality is solid and the after-sales team provided outstanding service.

18 May 2025

O

Oliver King

Great quality product! The after-sales service team was knowledgeable and catered to all my needs efficiently.

06 June 2025

L

Lily Martinez

This product is phenomenal! The quality is evident, and the after-sales team was brilliant in their support.

24 May 2025