Top Factories & Suppliers for Exceptional Thermal Resistance Solutions

Effective thermal management is essential for the success of your projects. At Kansd Precision Industry Co., Ltd., we specialize in delivering custom thermal resistance solutions designed to meet your unique specifications. As a trusted manufacturer, our advanced production methods ensure each component performs reliably and efficiently. We understand the importance of selecting the right partner for your business, which is why we emphasize quality and customer satisfaction. Our dedicated team collaborates closely with you to create tailored solutions that enhance your product's efficiency. With extensive industry experience, we are committed to providing superior thermal resistance products that endure over time. Partner with us to elevate your applications to new heights!

How To Evaluate thermal resistance Leads the Global Market Stands Out

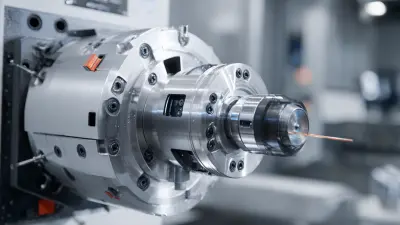

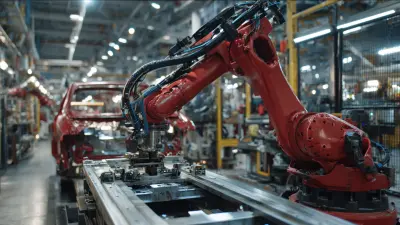

In the ever-evolving landscape of thermal resistance materials, evaluating the right components is crucial for companies looking to maintain a competitive edge in the global market. Thermal resistance plays a significant role in managing heat dissipation, which is essential for the reliable operation of electronic devices and automotive applications. As technology advances, the demand for materials that offer enhanced thermal performance continues to surge, emphasizing the need for precise manufacturing and assembly capabilities. One of the key aspects to consider when evaluating thermal resistance is the dimensional accuracy and reliability of the components. Precision Manufacturing, utilizing advanced CNC machines and lathes, ensures that each part meets stringent specifications, which is essential for optimal performance. Furthermore, thorough quality control processes involving CMM and 2D image measuring instruments confirm that every product adheres to the highest industry standards, providing procurement professionals with confidence in their sourcing decisions. Ultimately, choosing the right supplier is pivotal for achieving the desired thermal resistance properties in end products. By focusing on Precision Manufacturing techniques and stringent quality controls, businesses can differentiate themselves in the global market, ensuring their applications not only meet but exceed the expectations of end users. Effective collaboration with trusted manufacturers can lead to innovative solutions that enhance product performance and drive success.

How To Evaluate Thermal Resistance Leads the Global Market Stands Out

| Material Type | Thermal Conductivity (W/m·K) | thermal resistance (K/W) | Applications | Market Share (%) |

|---|---|---|---|---|

| Aluminum | 205 | 0.012 | Heat Sinks | 20% |

| Copper | 385 | 0.007 | Electronics Cooling | 30% |

| Graphene | 5000 | 0.002 | Advanced Thermal Management | 10% |

| Silicon | 150 | 0.015 | Semiconductor Devices | 15% |

| Ceramics | 25 | 0.04 | High-Temperature Applications | 25% |

Expert Choice of thermal resistance Manufacturer More Than a Supplier - A Partner

I

Isabella Lewis

Top-notch quality! The after-sales experience was made smooth by a team that genuinely knows their products.

25 June 2025

E

Emma Reed

The product quality is fantastic. The after-sales service was impressive, with knowledgeable staff always ready to help.

17 May 2025

W

William Shaw

This product is well-made and delivers excellent results. The follow-up service was conducted by highly knowledgeable staff.

23 May 2025

B

Benjamin Carter

Exceptional quality! The support team impressed me with their professionalism and willingness to assist.

01 July 2025

O

Oliver Perez

Quality and professionalism at its best! The support team answered all my questions swiftly.

01 July 2025

O

Oliver King

Great quality product! The after-sales service team was knowledgeable and catered to all my needs efficiently.

06 June 2025