Superior Machining: Quality Parts from Trusted Suppliers & Factories Worldwide

When it comes to exceptional machining solutions, I'm here to guide you to the best available options. With a commitment to quality and precision, I highly recommend suppliers with proven success in the industry. At Kansd Precision Industry Co., Ltd., we take pride in our advanced factory equipped with cutting-edge technology that delivers outstanding machining services. Our dedicated team ensures that every product adheres to the highest standards, customized to fit your specific requirements. By choosing us as your supplier, you invest in superior craftsmanship and foster a partnership built on reliability and clear communication. Our dedication to customer satisfaction will exceed your expectations. Contact us today to learn how we can support your business with our exceptional machining capabilities!Practical Methods To Superior Machining Ahead of the Curve Outperforms the Competition

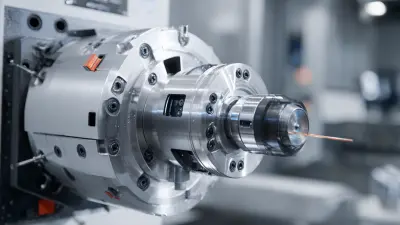

In today’s fast-paced manufacturing landscape, staying ahead of the curve is critical for success. Superior machining requires a combination of advanced technology, skilled personnel, and innovative practices. Employing CNC machines, lathes, and grinders allows manufacturers to create high-Precision Components that meet the demanding specifications of various industries. Leveraging these technologies not only enhances productivity but also ensures consistency and quality in the finished products. Moreover, the integration of precision measuring instruments, such as CMM and 2D imaging systems, plays a significant role in maintaining high standards throughout the production process. By implementing robust quality control measures and real-time monitoring, manufacturers can identify potential issues early and fine-tune their processes. Continuous improvement in machining techniques and equipment not only boosts operational efficiency but also positions companies to outperform their competitors in an ever-evolving market. Investing in research and development to explore new machining methods and materials can lead to innovative solutions that address specific client needs. These practical approaches ensure that your manufacturing processes remain agile and responsive, ultimately facilitating long-term relationships with global buyers looking for reliable and high-quality products. As the industry evolves, embracing these superior machining practices will be key to not only meeting but exceeding the expectations of your clients.

Practical Methods To Superior Machining Ahead of the Curve Outperforms the Competition

| Method | Description | Benefits | Efficiency Gain (%) | Comparison with Traditional Methods (%) |

|---|---|---|---|---|

| High-Speed Machining | Utilizes higher spindle speeds to reduce machining time. | Reduced cycle times, improved surface finish. | 30% | 20% |

| 5-Axis Machining | Machining with the ability to move the tool in five different axes. | Enhanced flexibility and precision, complex geometries. | 40% | 25% |

| Advanced Tooling | Using specialized tools designed for specific materials. | Longer tool life, reduced wear and tear. | 25% | 15% |

| Additive Manufacturing | Combining machining with 3D printing techniques. | Reduction in material waste, faster prototyping. | 50% | 30% |

| Digital Twin Technology | Using digital replicas for real-time monitoring and optimization. | Increased predictive maintenance, better workflow. | 35% | 20% |

Top 3 Superior Machining Manufacturers You Can Rely On Is The Best

E

Emma Smith

Quality products coupled with outstanding customer support. The professional approach of the staff left a lasting impression on me.

03 July 2025

S

Sofia Robinson

An amazing product with great attention to quality. The after-sales support was equally impressive from start to finish.

25 June 2025

Z

Zoe Powell

What an incredible product! The after-sales service team was quick, thorough, and very professional in their approach.

12 June 2025

M

Madison Diaz

Outstanding product! The support team was prompt and clear in their communication, which I greatly appreciated.

03 June 2025

S

Sophia Nelson

Great product quality! The after-sales service was second to none, with a staff that truly cares.

01 July 2025

A

Ava Martin

Fantastic items! The after-sales service experience was excellent, with a professional team who provided great support.

25 June 2025