01

Precision Medical Machining Services

2025-08-11

Providing Micron-Level Precision Key Components for the Life Sciences Field

Why Choose Our Medical Machining Services?

As precision machining experts certified to ISO 9001:2015, we specialize in providing the medical industry with customized components featuring high precision and strict tolerances (±0.0002 cm). Our services meet the manufacturing requirements throughout the process, from gene optical modules to surgical instruments.

Core Advantages

1. Medical-Grade Precision Manufacturing

The processing materials include biocompatible materials such as titanium alloy (Ti6Al4V), medical stainless steel (316L), PEEK, and cobalt-chromium alloy, which comply with ASTM F136 and ISO 13485 standards.

The tolerance control reaches ±0.0002 cm, meeting the high-precision requirements of optical inspection modules, surgical instruments, and other devices.

2. Full-Process Clean Production

Equipped with a Class 8 clean workshop to ensure that components are processed in a pollution-free environment. We support aseptic packaging (SIP/VHP) and surface treatments compatible with biofilms.

3. Integrated Value-Added Services

We provide post-processing techniques such as electrochemical polishing (ECP), passivation treatment, and laser marking to ensure that components meet FDA and CE certification requirements.

Key Application Areas

Typical Applications

Surgical Instruments: Endoscope components, minimally invasive surgical forceps, and precision parts of high-frequency electrosurgical knives.

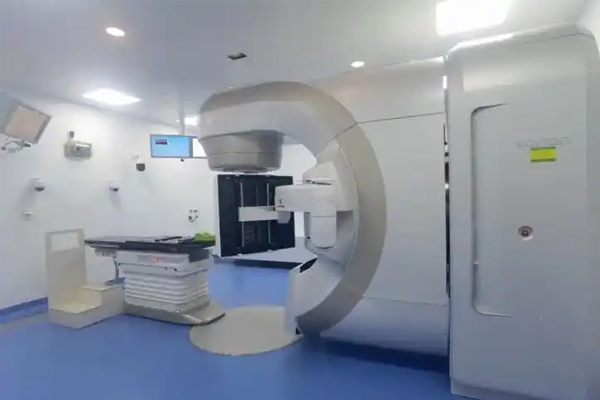

Diagnostic Equipment: CT/MRI equipment brackets, fluid control valves, and sensor housings.

Inspection Equipment: Optical inspection components and components of gene sequencing equipment.

Technical Capabilities

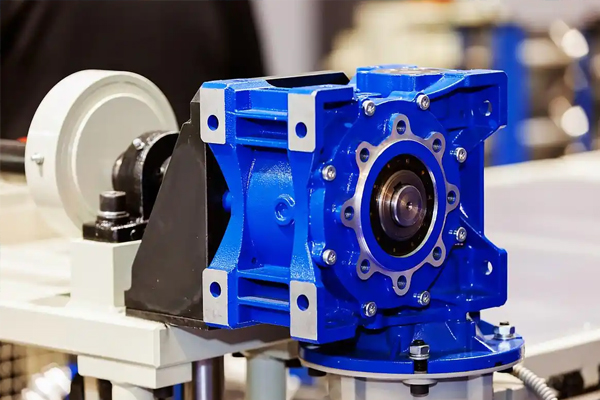

Multi-Axis machining: 5-axis CNC lathes support the machining of complex geometric shapes and micro features.

Precision Inspection System: We use Keyence image measurement systems and coordinate measuring machines (CMMs) to ensure a 100% full inspection pass rate.

Service Process

1. Requirement Docking: Submit drawings or samples (STEP/IGES/DWG formats are supported), and get a quotation within 48 hours.

2. Process Design: Our engineer team optimizes the DFM (Design for Manufacturability) to reduce production costs and delivery risks.

3. Flexible Production: We support orders starting from 1 piece, and emergency orders can be delivered in as fast as 5 days.

4. Quality Delivery: Along with the goods, we provide a full-size inspection report (FAI) and material certification (MTR).

Industry Recognition and Customer Testimonials

14 years of experience in the medical field, with over 2.5 million precision components delivered as of 2024.

Our clients include the world's top 10 medical device manufacturers, and our components are used in FDA Class III medical devices and CE-certified products.

Get Your Exclusive Quotation Now →

Submit your design requirements, and our engineers will contact you within 24 hours!

Additional Value

Non-Disclosure Agreement (NDA): We strictly protect customers' intellectual property rights and support customized encrypted delivery processes.

Global Logistics: We offer DDP/DAP terms covering North America, Europe, and the Asia-Pacific region.