01

Precision Machining Services for Energy and Industrial Equipment Manufacturing

2025-08-11

Create durable, stable, and efficient precision core components for the energy and industrial sectors!

Why choose Kansd Technology's precision machining services for energy and industrial equipment?

Kansd Technology Co., Ltd. (certified to ISO 9001:2015 quality management system and ISO 14001 environmental management system) has deeply penetrated the energy and industrial equipment manufacturing field. Specializing in high-precision machining, it is committed to producing equipment parts with micrometer-level accuracy (±0.003mm). Its business scope covers petrochemical equipment, power generation equipment, industrial robots, large-scale machinery, and other areas. Having delivered over 5 million high-quality parts, it helps customers enhance equipment performance and reduce operating costs with its outstanding product quality.

Core Advantages

1. Adaptive Material System

Full Material Coverage: It offers a complete range of materials, including carbon steel, alloy steel, stainless steel, various engineering plastics, and new composite materials, meeting the strict requirements of different equipment in terms of corrosion resistance, high-temperature resistance, and wear resistance.

Structural Adaptability: It is proficient in processing complex structural parts such as complex pipeline connectors in petrochemical equipment (ovality ≤ 0.05mm) and joint components of industrial robots (positioning accuracy ± 0.01mm).

2. Mass Production-Level Precision Control

Strict Tolerance Standards: The machining accuracy of CNC boring and milling is ±0.003mm, and the cylindricity of the grinding process is ≤0.002mm.

Runout Control: For high-speed rotating parts in power generation equipment, such as steam turbine rotors and motor shafts, the runout is strictly controlled to ≤0.003mm to ensure the stability of equipment operation.

3. Composite Process Capabilities

Surface Treatment Solutions: Chrome plating (thickness 0.02 - 0.05mm) can improve the surface hardness and wear resistance of parts; blackening treatment can enhance the anti-rust ability of metal surfaces.

Special Protection Processes: Thermal spraying of ceramic coatings (coating thickness 0.1 - 0.3mm) can extend the service life of equipment in high-temperature and high-wear environments; the application of a sealant coating process can ensure the equipment's tightness to meet the requirements of special working conditions.

Key Application Areas

1. Petrochemical Equipment

Refining Units: Internal components of reaction towers (dimensional tolerance ±0.05mm), pipeline valves (flatness of the sealing surface ≤0.003mm).

Chemical Equipment: Tube sheets of heat exchangers (hole pitch tolerance ±0.03mm), agitator shafts (straightness ≤0.05mm/m).

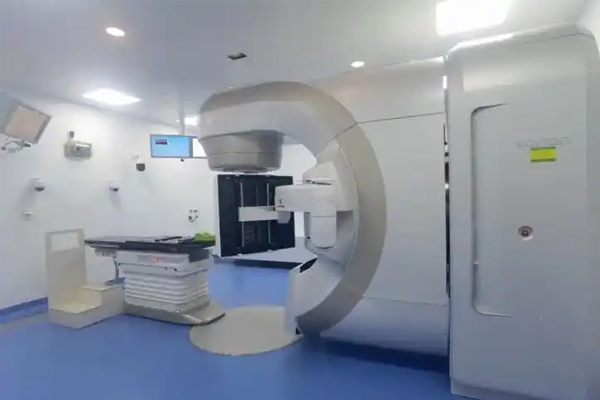

2. Power Generation Equipment

Thermal Power Generation: Steam turbine blades (profile error ≤0.05mm), generator end covers (fitting accuracy of the counterbore ±0.003mm).

Wind Power Generation: Hubs (coaxiality ≤0.005mm), main shafts (radial runout ≤0.003mm).

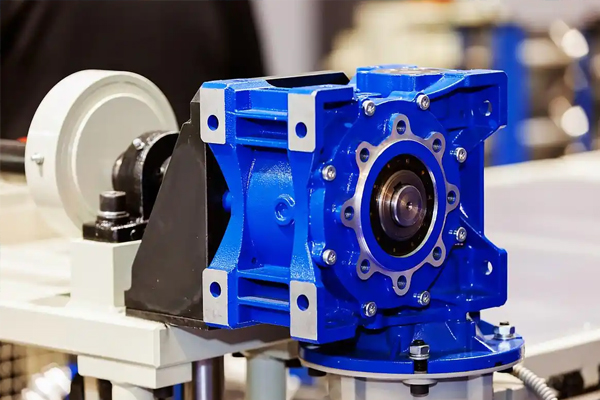

3. Industrial Robots and Automation Equipment

Industrial Robots: Reducer housings (position tolerance of positioning pin holes ±0.01mm), arm joint shafts (cylindricity ≤0.002mm).

Automated Production Lines: Sprockets of conveyor chains (tooth profile error ≤0.03mm), positioning fixtures (repeat positioning accuracy ±0.005mm).

Technical Capability Matrix

Indicator |

Parameter |

Highest Machining Accuracy |

Boring and milling ±0.003mm, Grinding ±0.002mm |

Typical Surface Roughness |

Ra0.2 - 1.6μm (special surface roughness can be customized) |

Batch Production Consistency |

CPK ≥ 1.67 (100% full inspection of critical dimensions) |

Complex Structure Machining |

Minimum hole diameter 0.5mm, depth-to-diameter ratio 10:1 |

Monthly Standardized Production Capacity |

1 million energy and industrial equipment parts, emergency orders can be responded to within 3 days |

Service Process

1. Requirement Confirmation: Receive drawings/3D models (compatible with mainstream design software formats) and provide professional DFM manufacturability analysis to optimize product designs for customers.

2. Process Development: Develop a scientific and reasonable process route and complete a detailed PPAP document package (including PSW and MSA reports).

3. Pilot Production Verification: Deliver samples and full-size inspection reports to ensure that product quality meets industry standards.

4. Mass Production Management: Implement SPC process monitoring, adopt an advanced production management system to ensure production progress, and support JIT just-in-time delivery.

Industry-Recognized Cases

Petrochemical Pipeline Project: Mass-produced pipeline connectors for a large petrochemical enterprise, with the ovality controlled within 0.05mm, effectively improving the sealing and safety of the pipeline system and reducing the leakage risk.

Wind Turbine Hub Machining: Provided hub machining services for a wind power equipment manufacturer, with the coaxiality reaching ≤0.005mm, significantly improving the power generation efficiency and operation stability of wind turbines.

Industrial Robot Reducer Housing: Machined reducer housings for a robot manufacturing enterprise, with the position tolerance of positioning pin holes at ±0.01mm, enhancing the motion accuracy and working stability of robots.

Additional Value

Compliance Assurance: Establish a complete material traceability system to achieve full-process traceability from raw material procurement to product delivery, and support the submission of various material compliance reports.

Technical Collaborative Development: Collaborate deeply with customers to overcome the machining challenges of key components of a new industrial equipment. By optimizing the process, production costs are reduced, and product quality is improved.

After-Sales Technical Support: Provide professional after-sales technical support to assist customers in solving problems during equipment operation and extend the equipment's service life.

Get a precision machining solution for energy and industrial equipment now

Submit your technical specifications and receive a complete process plan and tiered quotation within 24 hours!