01

Precision Machining Services for Auto Parts in the Automotive Manufacturing Industry

2025-08-11

Providing High-Precision Core Components for Traditional Combustion Engine and New Energy Vehicles

Why choose Kansd's auto parts machining services?

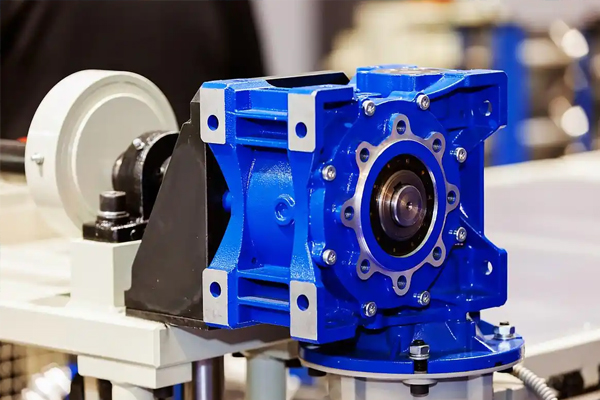

Shenzhen Kansd Technology Co., Ltd. (certified to ISO 9001:2015 & IATF 16949) has been deeply engaged in the automotive manufacturing field. It focuses on machining metal parts with micrometer-level accuracy (±0.002mm), covering areas such as engine systems, transmission mechanisms, and the "Three-Electrics" of new energy vehicles. With over 8 million vehicle-grade parts delivered, it helps customers enhance the reliability of complete machines and the yield rate of production lines.

Core Advantages

1. Vehicle-Grade Material System

Full Material Coverage: Aluminum alloys (ADC12/A356), nodular cast iron (QT500), stainless steel (17 - 4PH), titanium alloys (TA2/TC4), etc. These materials can meet the requirements of lightweight design, high-pressure resistance, and extreme operating conditions.

Structural Compatibility: It supports the machining of complex thin-walled parts such as high-pressure fuel rails and turbocharger blades (wall thickness 0.8mm ± 0.05mm).

2. Mass Production-Level Precision Control

Strict Tolerance Standards: The machining accuracy of CNC turning is ±0.003mm, and the flatness achieved by the grinding process is ≤0.001mm.

Dynamic Balance Calibration: For rotating parts like engine crankshafts and motor rotors, G2.5 - class dynamic balance correction is provided.

3. Composite Process Capabilities

Wear-Resistant Enhancement Solutions: High - frequency quenching (hardness HRC58 - 62), nitriding treatment (case depth 0.2 - 0.3mm), DLC coating (friction coefficient ≤ 0.1).

Sealing Surface Treatments: End-face mirror polishing (Ra ≤ 0.1μm), micro - arc oxidation (withstand voltage ≥ 1000V), which are suitable for the sealing requirements of new energy battery boxes.

Key Application Areas

1. Powertrain System

Engine Components: High - pressure common - rail fuel injectors (hole diameter Φ0.12mm ± 0.002mm), turbocharger housings.

Transmission Parts: Planetary gear sets (tooth profile error ≤ 3μm), precision valve bodies for dual - clutch modules.

2. Three-Electrics System of New Energy Vehicles

Electric Drive Unit: Motor housings (coaxiality ≤ 0.008mm), water - cooled end covers (surface roughness of the flat sealing surface Ra0.4μm).

Battery System: Aluminum alloy battery trays (welding pre - machining accuracy ± 0.05mm), busbar copper bars (with silver - plated conductive surfaces).

3. Chassis and Safety System

Brake Components: ABS valve bodies (inner hole cylindricity ≤ 0.005mm), caliper pistons (diameter tolerance ± 0.003mm).

Steering Mechanisms: EPS sensor brackets (position tolerance ± 0.01mm), rack - and - pinion pairs (meshing clearance ≤ 0.02mm).

Technical Capability Matrix

Indicator |

Parameter |

Highest Machining Accuracy |

Turning ±0.003mm, Grinding ±0.001mm |

Typical Surface Roughness |

Ra0.2 - 0.8μm (mirror polishing can be customized) |

Batch Production Consistency |

CPK ≥ 1.67 (100% full inspection of critical dimensions) |

Lightweight Structure Machining |

Aluminum alloy thin - walled parts ≥ 0.5mm, holes with a depth - to - diameter ratio of 15:1 |

Monthly Standardized Production Capacity |

1.5 million metal parts, emergency orders can be responded to within 3 days |

Service Process

1 .Requirement Confirmation: Receive drawings/3D models (in CATIA/UG/NX formats) and provide DFM manufacturability analysis.

2. Process Development: Develop an APQP process and complete the PPAP document package (including PSW and MSA reports).

3. Pilot Production Verification: Deliver OTS samples and full - size reports (in compliance with VDA 6.3 standards).

4. Mass Production Management: Implement SPC process monitoring and support JIS/JIT sequential supply.

Industry-Recognized Cases

New Energy Battery Tray Project: Mass - produced one - piece die - cast aluminum alloy trays (dimensional tolerance ±0.1mm/800mm) for a leading automaker, with a yield rate of 99.8%.

48V Mild Hybrid System Components: Machined BSG motor housings (cylindricity ≤ 0.01mm) for Bosch's supply chain.

Intelligent Chassis Sensors: Delivered millimeter - wave radar brackets (aluminum alloy + plastic composite machining), meeting the operating conditions from - 40°C to 125°C.

Additional Value

New Energy Battery Tray Project: Mass - produced one - piece die - cast aluminum alloy trays (dimensional tolerance ±0.1mm/800mm) for a leading automaker, with a yield rate of 99.8%.

48V Mild Hybrid System Components: Machined BSG motor housings (cylindricity ≤ 0.01mm) for Bosch's supply chain.

Intelligent Chassis Sensors: Delivered millimeter - wave radar brackets (aluminum alloy + plastic composite machining), meeting the operating conditions from - 40°C to 125°C.