Top Precision Wire EDM Suppliers and Effective Factory Solutions Unveiled

At Kansd Precision Industry Co., Ltd., we specialize in high-quality Precision Wire EDM solutions designed to meet your operational needs. With advanced technology and a dedicated team, our products adhere to strict industry standards, ensuring reliability and excellence for your business operations. Choose us for precision and quality in every project.Reasons to Choose Precision Wire Edm From Concept to Delivery Now Trending

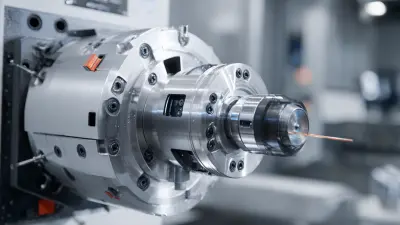

Precision Wire EDM (Electrical Discharge Machining) is rapidly gaining traction among global manufacturers due to its unparalleled accuracy and versatility in producing intricate parts. This technology offers a solution for creating complex geometries that traditional machining methods struggle to achieve. As industries increasingly demand Precision Components, the ability to streamline production from concept to delivery becomes critical for maintaining a competitive edge. Wire EDM stands out by providing exceptional repeatability and surface finish, making it the ideal choice for high-tolerance applications across various sectors, including aerospace, automotive, and medical devices. Moreover, advancements in CNC technology have enhanced efficiency and reduced lead times. With the capability to work on a wide range of materials—from hard metals to exotic alloys—precision wire EDM can cater to the diverse needs of global procurement professionals. Coupled with state-of-the-art measuring instruments, such as CMM and 2D image measuring tools, manufacturers can ensure that every component meets stringent quality standards while minimizing waste and production costs. Selecting precision wire EDM not only means investing in high-quality parts but also embracing a manufacturing process that adapts to changing market demands. By choosing this technology, businesses can enhance their operational efficiency, accelerate time-to-market, and ultimately achieve greater customer satisfaction. If you're looking to stay ahead in the competitive manufacturing landscape, now is the time to explore the advantages of precision wire EDM from concept to delivery.

Reasons to Choose Precision Wire Edm From Concept to Delivery Now Trending

| Dimension | Description | Advantages |

|---|---|---|

| Accuracy | Ensures high precision cuts on various materials. | Minimal tolerances leading to better product fit. |

| Versatility | Can work with a variety of conductive materials. | Ideal for complex geometries and intricate designs. |

| Surface Finish | Provides a smooth surface finish without additional machining. | Reduces secondary processing time and costs. |

| Speed | Fast processing times for prototypes and production parts. | Quick turnarounds reduce lead times. |

| Cost-Effectiveness | Minimized waste and efficient material usage. | Lower total manufacturing costs. |

Smart Ways To Precision Wire Edm Delivers Unmatched Quality Outperforms the Competition

M

Michael Sampson

The product quality exceeded my expectations. The support team was incredibly responsive and professional, making the entire experience seamless.

25 June 2025

M

Madison Diaz

Outstanding product! The support team was prompt and clear in their communication, which I greatly appreciated.

03 June 2025

S

Sophia Nelson

Great product quality! The after-sales service was second to none, with a staff that truly cares.

01 July 2025

N

Noah Miller

Very happy with the purchase! The quality is excellent, and I appreciate the responsiveness of the support team.

28 May 2025

J

Jackson Taylor

The quality is outstanding! I was very pleased with how professional the support team was during my inquiry.

07 June 2025

G

Grace Torres

I am very pleased with my choice. The quality is excellent, and the support staff is ever so professional.

23 May 2025