Precision Parts Material Guide: Quality Insights from Top Factory Manufacturers

Sourcing precision parts requires a thorough understanding of material options to make well-informed choices. Our Precision Parts Material Guide offers valuable insights into various materials, enabling you to select the best fit for your project. As a prominent manufacturer and supplier, we are dedicated to providing custom solutions tailored to your specific needs, ensuring superior quality and performance. With extensive experience, I can guide you through the properties and applications of each material, whether you're producing prototypes or scaling up for larger production runs. Effective communication is a priority, and I am here to support you at every step. Whether you require technical data or assistance with your order, our commitment to your satisfaction remains unwavering. Together, we can create precision parts that fulfill your exact specifications.

The Secret to Precision Parts Material Guide Sets the Industry Standard Factory

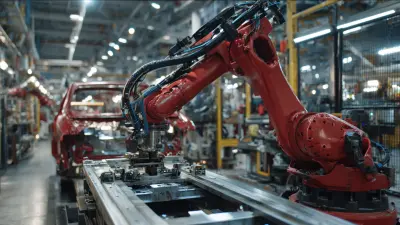

In today’s fast-paced manufacturing environment, precision is not just a luxury; it’s a necessity. The evolution of precision parts has led industries to seek materials and production techniques that adhere to the highest standards. Understanding the right materials for manufacturing precision parts can significantly influence product quality, reliability, and overall success in the market. This is where a comprehensive materials guide comes into play. Our guide outlines various material options that cater to specific applications and performance requirements, helping global procurement professionals make informed decisions. Whether you’re working with metals, plastics, or composites, each material presents unique properties that can enhance or hinder production efficiency and product longevity. Key factors to consider include tensile strength, machinability, corrosion resistance, and thermal stability. By leveraging advanced manufacturing techniques, such as CNC machining and precision lathing, industries can achieve unparalleled accuracy, paving the way for innovative product designs and streamlined assembly processes. Investing in precision parts made from high-quality materials not only fosters product reliability but also supports sustainable practices in manufacturing. Understanding the link between material selection and production excellence is vital for companies eager to set industry standards. With the right expertise and resources, businesses can confidently navigate the complexities of Precision Manufacturing, ensuring they meet the demands of a competitive global market.

The Secret to Precision Parts Material Guide Sets the Industry Standard Factory

| Material Type | Mechanical Properties | Applications | thermal resistance (°C) | Cost per kg (€) |

|---|---|---|---|---|

| Aluminum Alloy 6061 | Tensile Strength: 310 MPa | Aerospace, Automotive | 200 | 2.50 |

| Stainless Steel 316 | Tensile Strength: 580 MPa | Marine, Food Processing | 870 | 5.00 |

| Mild Steel S235 | Tensile Strength: 370 MPa | Construction, Manufacturing | 400 | 0.90 |

| Titanium Alloy Ti-6Al-4V | Tensile Strength: 900 MPa | Aerospace, Biomedical | 600 | 45.00 |

| Polycarbonate (PC) | Impact Strength: 900 J/m² | Optical, Electrical | 115 | 3.00 |

Best Way To Choose Precision parts Material Guide Leads the Global Market Is The Best

E

Emily White

Excellent craftsmanship! The after-sales service was handled by knowledgeable professionals who really cared.

01 July 2025

L

Liam Taylor

Great product! The support team made the experience enjoyable with their prompt replies and expert advice.

04 July 2025

H

Harper Flores

Incredible quality from start to finish. The professionalism of the after-sales team is commendable!

22 June 2025

L

Liam Garcia

Highly impressed! The product quality is exceptional, and the customer service team showed utmost professionalism.

29 June 2025

E

Emma Hernandez

Wonderful product! The after-sales team was efficient and very knowledgeable, providing the support I needed.

27 May 2025

S

Sophia Martinez

What a great experience! The product is excellent, and the customer service team was professional and supportive.

12 June 2025