Top Precision Metal Parts Supplier for Quality Manufacturing Solutions

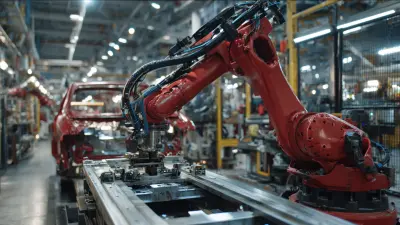

At our facility, we specialize in producing high-quality Precision Metal Parts tailored to the diverse demands of various industries. As a trusted manufacturer, we employ advanced machinery and skilled craftsmanship, ensuring that each component meets the highest standards of excellence. Whether you require custom solutions or standard components, our factory is fully equipped to handle orders of any size while maintaining exceptional quality. We prioritize not just product delivery but also peace of mind by thoroughly understanding your specific requirements and providing customized solutions that align with your business needs. Partnering with Kansd Precision Industry Co., Ltd. grants you access to an extensive range of metal parts designed to enhance your operations and improve efficiency. Let's achieve precision and excellence together in every piece we produce!Best Methods To Precision Metal Parts Factory Products

In the competitive landscape of Precision Manufacturing, finding reliable partners for high-quality metal parts production is crucial for global buyers. Precision metal parts are foundational in numerous industries, including automotive, aerospace, electronics, and medical devices. To ensure the best results, it’s essential to understand the best methods for sourcing these components from a factory proficient in precision machining and assembly. One of the most effective approaches is to partner with a factory that utilizes advanced CNC machining techniques. These machines enable high accuracy and repeatability, essential for producing intricate components that meet exact specifications. Moreover, employing a variety of machinery, such as lathes, milling machines, and grinding machines, allows manufacturers to offer a wide range of services, ensuring flexibility in production. A facility equipped with medium-speed wire cutting machines can also provide detailed cuts necessary for complex component outlines, while advanced measurement tools like CMM and 2D image measuring instruments guarantee quality control at every stage. Additionally, fostering a strong communication line with the factory can significantly enhance the efficiency of the procurement process. Providing detailed specifications, engaging in revision discussions, and requesting prototypes can pave the way for smoother transitions from concept to production. By focusing on these methods, global buyers can establish fruitful partnerships that ensure the delivery of precision metal parts that not only meet but exceed industry standards.

Best Methods To Precision Metal Parts Factory Products

| Method | Description | Advantages | Applications |

|---|---|---|---|

| Cnc Machining | A computer-controlled method using precise cutting tools. | High accuracy, ability to create complex shapes. | Aerospace, Automotive, Medical Devices |

| Laser Cutting | Utilizes focused laser beams to cut materials with precision. | Minimal material waste, intricate designs possible. | Signage, Sheet Metal Fabrication |

| EDM (Electrical Discharge Machining) | Uses electrical sparks to erode metal and shape parts. | Excellent for hard metals, high precision. | Tooling, Molds, Aerospace Components |

| 3D Printing | Additive manufacturing using layers of materials to build parts. | Rapid prototyping, complex geometries. | Prototyping, Custom Parts |

| Stamping | A process using dies to shape metal sheets by applying force. | High speed, cost-effective for large volumes. | Automotive, Electronics, Appliances |

Key Methods For Precision Metal Parts Winning in 2025 Your Trusted OEM Partner

A

Ava Baker

Incredible product quality. The support team was quick, friendly, and professional, ensuring all my questions were addressed.

26 May 2025

O

Owen Davis

Very pleased with this purchase! The quality is noticeable, and the staff were incredibly professional and helpful.

30 June 2025

O

Oliver King

Very impressed with the overall product quality. The professionalism of the support team made the experience so much better.

11 May 2025

E

Eli Bell

What a fantastic product! The level of support from the team was impressive and made my experience effortless.

30 June 2025

J

James Turner

Incredible purchase! The quality has exceeded my expectations, and the support team was professional and responsive.

19 May 2025

M

Michael Allen

Excellent quality! The after-sales service was prompt, with an incredibly knowledgeable team.

01 July 2025