Precision Machining Technology: Guide to Custom Suppliers and Manufacturers

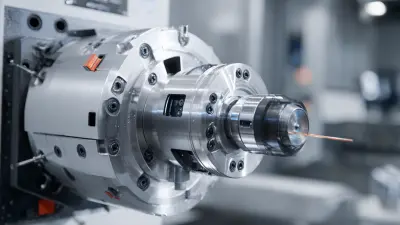

At Kansd Precision Industry Co., Ltd., we specialize in high-quality Precision Machining Technology customized for B2B purchasers. Our advanced factory is equipped with state-of-the-art machinery, ensuring meticulous attention to detail in every project. As an experienced manufacturer, we recognize the critical role of reliable components in your production process. Our precision machining solutions are crafted to enhance efficiency, minimize waste, and deliver outstanding performance. By choosing our services, you partner with a dedicated team focused on quality and innovation. We aim to provide tailored solutions that align seamlessly with your operational needs, regardless of your requirements. Count on us for exceptional products that empower your business and keep you at the forefront of your industry. Let’s collaborate to achieve your precision machining objectives and optimize your production processes.How To Compare Precision Machining Technology Guarantees Peak Performance Service

When it comes to sourcing Precision Machining Technology, understanding the guarantees of peak performance service is crucial for global buyers. The rapid advancements in CNC machinery and precision assembly processes have reshaped the manufacturing landscape, making it essential to choose a partner that not only possesses cutting-edge equipment but also demonstrates a commitment to quality and service excellence. The evaluation process should begin with an assessment of the technology offered. Look for suppliers with a diverse range of capabilities, including CNC machines, lathes, milling machines, and advanced measuring instruments. These tools are the backbone of precision engineering, enabling the production of components that meet stringent tolerance levels and specifications. Additionally, inquire about the training and expertise of the operators, as skilled personnel play a critical role in ensuring consistent quality. Equally important is the supplier's service infrastructure. A robust customer support system, including after-sale services and technical assistance, enhances the overall buyer experience. Transparency in communication, timely delivery, and the ability to adapt to changing requirements are key indicators of a reliable manufacturing partner. By focusing on these aspects, global buyers can confidently select a supplier that guarantees peak performance in Precision Machining Technology, ensuring their projects are completed to the highest standards.

How To Compare Precision Machining Technology Guarantees Peak Performance Service

| Aspect | Description | Technology Type | Performance Metric | Rating (1-10) |

|---|---|---|---|---|

| Accuracy | Ability to produce parts within specified tolerances. | CNC Machining | Tolerance Level | 9 |

| Surface Finish | Quality of the surface after machining. | Laser Machining | Ra Value | 8 |

| Turnaround Time | Time taken from order to delivery of parts. | 5-Axis Machining | Lead Time | 7 |

| Machining Speed | Rate of material removal during machining. | EDM (Electrical Discharge Machining) | Cutting Rate | 8 |

| Material Versatility | Ability to handle various materials. | Milling | Material Range | 9 |

China’s Best-Selling Precision Machining Technology Manufacturers You Can Rely On More Than a Supplier - A Partner

L

Liam Taylor

Great product! The support team made the experience enjoyable with their prompt replies and expert advice.

04 July 2025

Z

Zoe Powell

What an incredible product! The after-sales service team was quick, thorough, and very professional in their approach.

12 June 2025

W

William Shaw

This product is well-made and delivers excellent results. The follow-up service was conducted by highly knowledgeable staff.

23 May 2025

L

Liam Garcia

Highly impressed! The product quality is exceptional, and the customer service team showed utmost professionalism.

29 June 2025

J

Jackson Taylor

The quality is outstanding! I was very pleased with how professional the support team was during my inquiry.

07 June 2025

O

Oliver King

Great quality product! The after-sales service team was knowledgeable and catered to all my needs efficiently.

06 June 2025