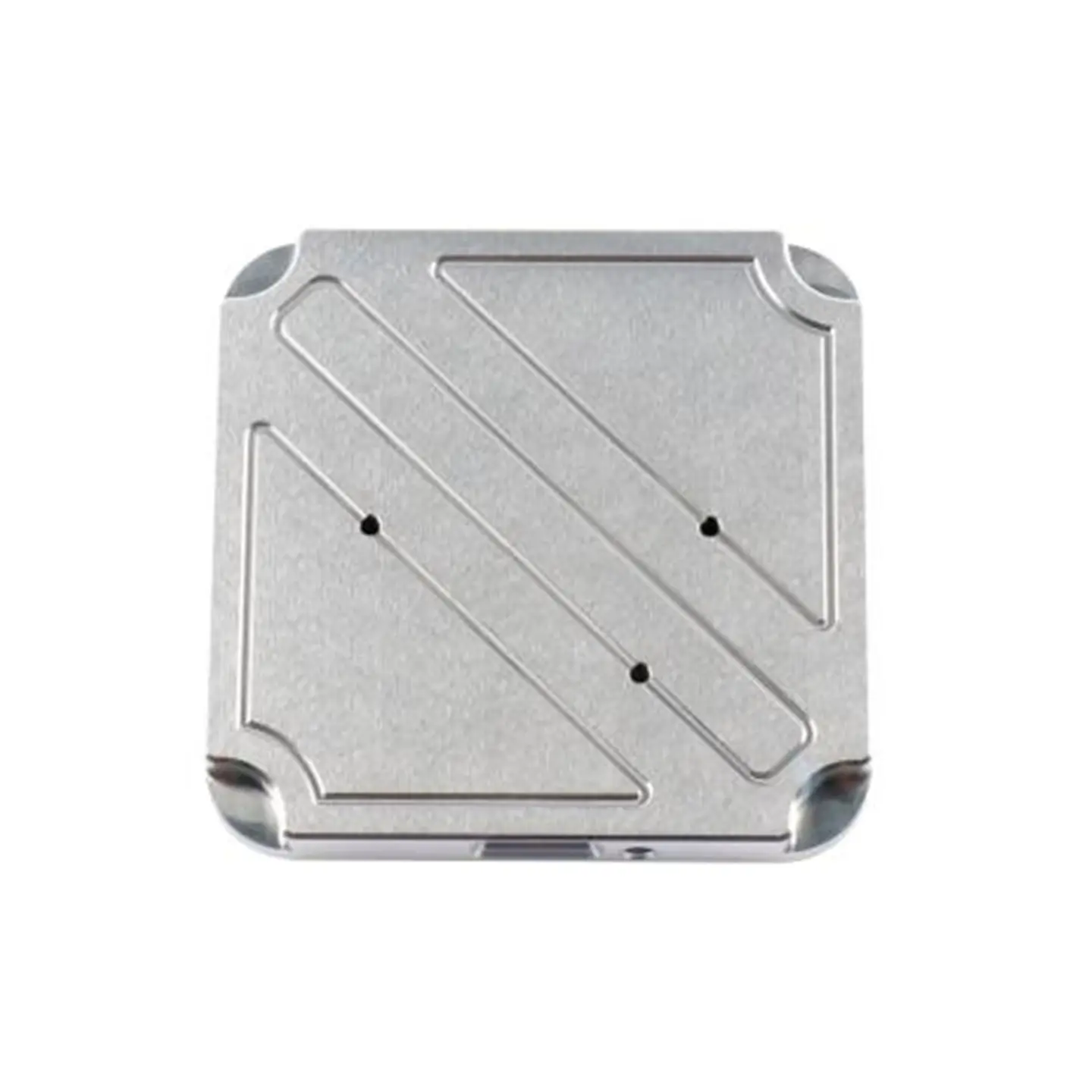

Precision Machining Case Study – Medical-Grade SUS316L Adsorption Plate

Project Overview

In the medical device industry, the choice of materials and the level of machining precision directly determine the safety, functionality, and reliability of the final product. This adsorption plate is manufactured using medical-grade SUS316L stainless steel, a material widely recognized for its superior corrosion resistance and biocompatibility, far outperforming standard grades like SUS303.

2.Machining Challenges

• High Material Hardness

SUS316L contains molybdenum, giving it a Brinell hardness over 180HB—significantly harder than SUS303. During CNC milling and turning, this leads to greater tool wear. Standard HSS tools wear 3–5 times faster when machining SUS316L, requiring the use of high-performance coated carbide tools and optimized cutting parameters to maintain precision and extend tool life.

• Extreme Surface and Cleanliness Requirements

As a critical medical component, the surface must be completely free of scratches, dents, or oxidation marks. To achieve this:

Custom fixtures are used to avoid clamping damage.

Dust-free transfer boxes with pearl cotton films protect the surface between processes.

Strict environmental controls are implemented to avoid contamination.

• High Material Cost and Zero-Waste Requirement

SUS316L is twice as expensive as SUS303, which leaves no room for waste. From raw stock cutting to finishing, every process is optimized to maximize material utilization and reduce unnecessary scrap.

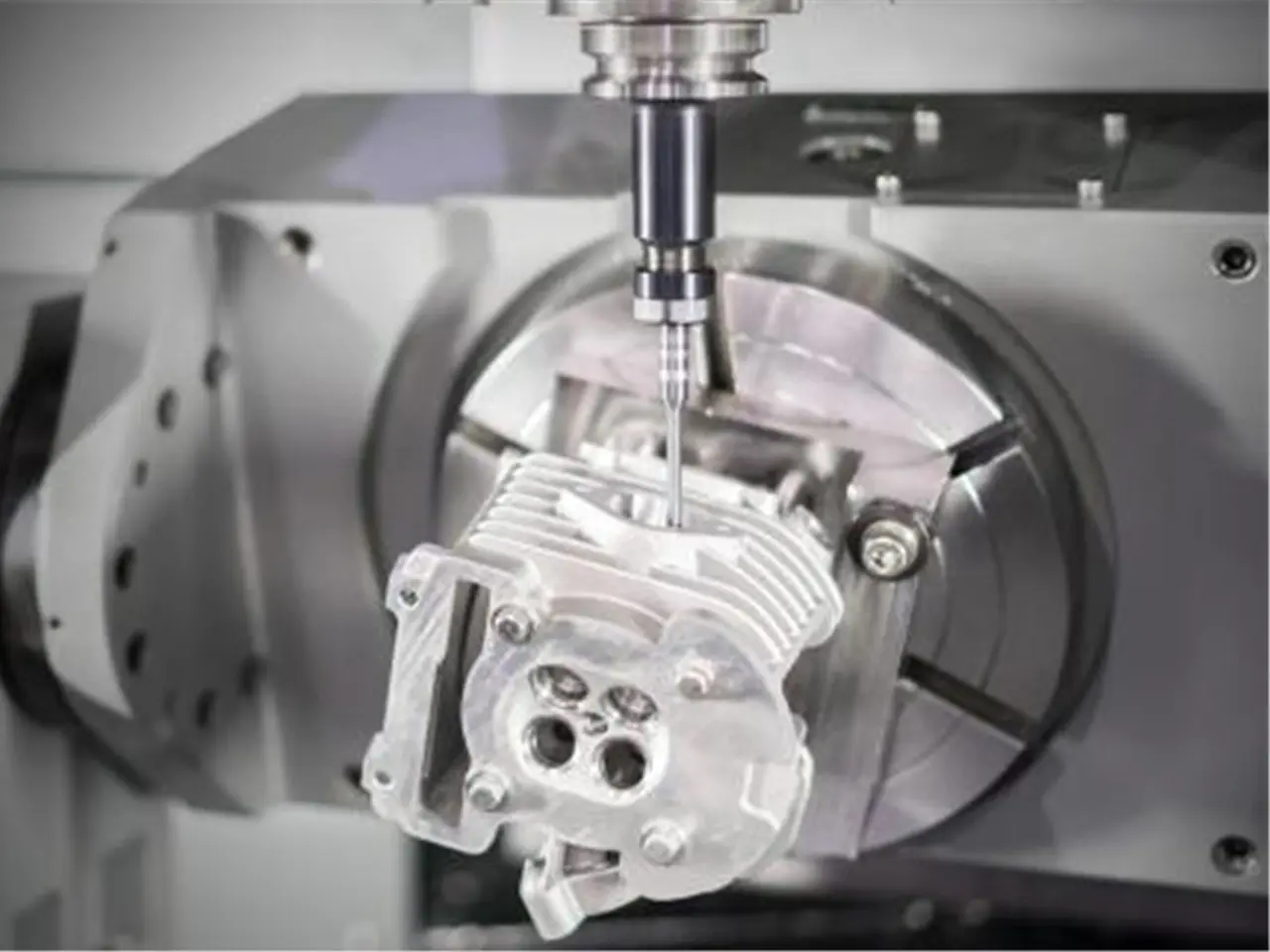

Machining Process & Technical Highlights

The final product undergoes 13 machining operations from raw material to finished part. The process concludes with precision grinding, achieving a mirror-like surface finish with Ra ≤ 0.4μm. Key processes include:

High-precision CNC rough and finish milling

Multi-axis coordinated hole drilling

Custom fixture clamping for accurate positioning

Mirror surface grinding and polishing

100% in-process and final inspection of critical dimensions and appearance

Each step is fully traceable and controlled under the ISO 13485 quality management system for medical devices, ensuring the product meets stringent regulatory and clinical standards.

Why Choose Us for SUS316L Medical Components?

This project demonstrates our advanced capabilities in precision machining of hard-to-machine medical-grade materials, especially stainless steel parts with tight tolerances and strict surface requirements. We offer:

±0.002mm machining tolerance

Over 13 years of experience in medical component manufacturing

ISO 9001 & ISO 13485 certified quality systems

Cleanroom-level handling and packaging protocols

Full-process quality control and documentation

Company Profile

14+

years

Kansd was established in 2011. As an enterprise specializing in precision manufacturing and assembly, we located in Shenzhen,China. With more than 70 professional employees, Kansd has a professional technical team that has been deeply engaged in the precision manufacturing industry for more than ten years.

- One-stop service

- High quality products

- Advanced production equipment

- OEM&ODM services