Top Precision Machining Case Studies: Insights on Leading Suppliers and Factories

At Kansd Precision Industry Co., Ltd., we specialize in custom manufacturing that meets the most intricate specifications with precision and skill. Our commitment to excellence is evident through our collaborative approach to creating parts that fully align with our clients' expectations. Our case studies highlight not only our technical expertise but also our unwavering dedication to customer satisfaction. Partnering with us means choosing a professional team that places a strong emphasis on high-quality craftsmanship. Let's elevate your projects with our proven track record in precision machining.Best Methods To Precision Machining Case Studies Service Backed by Expertise Your End-to-End Solution

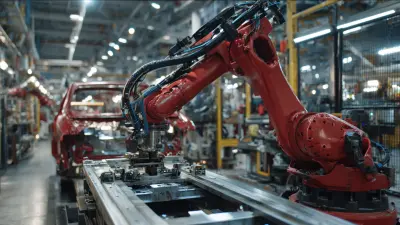

In today's competitive landscape, precision machining is paramount for industries demanding high-quality components. Implementing best practices in precision machining not only enhances product quality but also drives efficiency and cost-effectiveness. Case studies from leading organizations highlight the importance of investing in advanced machinery and skilled personnel. Utilizing CNC machines, lathes, and milling machines allows experts to achieve tight tolerances and intricate designs, providing clients with solutions tailored to their specific needs. One key to success in precision machining is adopting a customer-centric approach. This includes offering end-to-end solutions, from the initial design phase to final assembly. Collaborating closely with clients enables companies to fully understand their requirements and challenges, ensuring that the manufactured parts meet stringent specifications. Additionally, employing state-of-the-art inspection tools, such as coordinate measuring machines (CMM) and 2D image measuring instruments, guarantees that each component is meticulously checked for quality prior to delivery. Investing in continuous improvement and staff training is critical for maintaining a competitive edge in the precision machining sector. By fostering an environment of expertise, organizations can leverage the latest technologies and methodologies to streamline operations and minimize errors. This dedication to excellence not only builds trust with global buyers but also positions companies as reliable partners capable of delivering high-performing, precision-engineered products.

Best Methods To Precision Machining Case Studies Service Backed by Expertise Your End-to-End Solution

| Case Study | Industry | Machining Method | Project Duration | Outcome |

|---|---|---|---|---|

| Precision Engine Components | Automotive | CNC Milling | 3 Months | Increased efficiency by 20% |

| Customized Aerospace Parts | Aerospace | EDM (Electrical Discharge Machining) | 4 Months | Achieved zero defects in testing phase |

| Medical Device Components | Medical | CNC Turning | 2 Months | Reduced production costs by 15% |

| High-Precision Gear Parts | Industrial Equipment | Grinding | 5 Months | Improved performance standards |

| Consumer Electronics Parts | Electronics | Laser Cutting | 1 Month | Enhanced product design flexibility |

Must-Know Tips For Precision Machining Case Studies in 2025 Ahead of the Curve

M

Mia Clark

I was thoroughly impressed with the product and the follow-up service. The team was knowledgeable and genuinely cared about meeting my needs.

30 May 2025

C

Chloe Harris

I absolutely love this product! The quality is unmatched, and the responsive after-sales team was a huge plus.

09 June 2025

O

Oliver King

Very impressed with the overall product quality. The professionalism of the support team made the experience so much better.

11 May 2025

C

Chloe Carter

This product is top quality! The after-sales staff were very professional and knowledgeable, making the experience great.

06 July 2025

E

Ethan Lopez

Great value for quality! The service received was friendly and professional, making for a smooth experience.

04 June 2025

L

Liam Nelson

Very happy with this purchase! The craftsmanship is impressive, and the after-sales service was exemplary.

04 June 2025