Top Suppliers & Manufacturers for Precision Optical Testing Component Machining

When it comes to Optical Testing Component Machining, precision and quality are paramount. As a reliable supplier, I offer exceptional machining services tailored to your unique requirements. Our advanced factory technology ensures that every component adheres to strict standards for optical testing applications. I am committed to providing you with the best solutions that facilitate seamless integration into your projects. Collaboration with my dedicated team guarantees that we meet your exact specifications, whether you need prototypes or large-scale production. Choosing the right supplier can greatly impact your success, and I strive for your satisfaction with each order. Trust in excellence for Optical Testing Component Machining, and let’s work together to achieve your business objectives.How To Optical Testing Component Machining From Concept to Delivery Factory-Direct Excellence

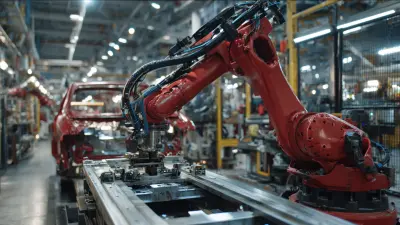

When it comes to Optical Testing Component Machining, the path from concept to delivery is crucial for ensuring factory-direct excellence. Precision in manufacturing and assembly plays a significant role in achieving high-quality optical components. The machining process begins with a thorough understanding of the client's specifications and requirements. Utilizing advanced CNC machines and other precision equipment, manufacturers can produce intricate components with exceptional accuracy and consistency. Throughout the production cycle, strict quality control measures are implemented, utilizing tools such as CMM and 2D image measuring instruments to uphold the highest standards. From the initial design phase to prototyping and final production, every step is meticulously monitored to ensure each component meets optical testing criteria and industry regulations. This commitment to precision not only enhances product performance but also builds trust with clients seeking reliable solutions for their optical needs. Moreover, an efficient delivery system ensures that your components arrive on time and in perfect condition. By streamlining logistics and maintaining strong communication channels, manufacturers can provide a seamless experience for global buyers. This level of dedication to quality and service positions machining providers as leaders in the optical component industry, capable of driving innovation and meeting the evolving demands of clients worldwide.

| Phase | Description | Duration | Key Technologies | Quality Assurance |

|---|---|---|---|---|

| Conceptual Design | Initial design drafts and feasibility studies. | 2 weeks | CAD Software, Simulation Tools | Design Reviews, Prototype Testing |

| Prototyping | Development of a physical prototype for testing. | 3 weeks | 3D Printing, CNC Machining | Functional Testing, Performance Evaluation |

| Production Planning | Finalizing production methods and logistics. | 1 week | ERP Systems, Lean Manufacturing | Supply Chain Validation, Risk Assessment |

| Manufacturing | Production of components based on finalized designs. | 4 weeks | Automated Machinery, Quality Control Tools | In-Process Inspections, Quality Checks |

| Delivery | Shipping of finished products to the client. | 1 week | Logistics Management Software | Post-Delivery Evaluation, Customer Feedback |

How To Find The Best Optical Testing Component Machining Market Leader Winning in 2025

I

Isabella Lewis

Top-notch quality! The after-sales experience was made smooth by a team that genuinely knows their products.

25 June 2025

H

Harper Flores

Incredible quality from start to finish. The professionalism of the after-sales team is commendable!

22 June 2025

E

Ella Walker

Top-notch product! The after-sales service went beyond expectations, with a knowledgeable team on hand.

05 June 2025

O

Oliver Scott

Excellent quality! The after-sales support was professional, ensuring I was informed and satisfied.

16 June 2025

J

Jackson Taylor

The quality is outstanding! I was very pleased with how professional the support team was during my inquiry.

07 June 2025

E

Emma Young

This product is life-changing! The quality is top-tier, and so was the support provided post-purchase.

31 May 2025