Top Custom Optical Precision Machining Manufacturers & Suppliers - Quality Solutions

At Kansd Precision Industry Co., Ltd., we excel in Optical Precision Machining that adheres to the most stringent industry standards. Our custom solutions are tailored to meet the specific requirements of businesses, ensuring that each component is crafted with meticulous attention to detail. We understand the critical importance of accuracy and reliability in your projects, which is why we are committed to delivering products that enhance your operational efficiency. Our team collaborates closely with you, offering expert guidance throughout the entire process. From prototypes to large-scale production, we possess the expertise and technology to support your needs while maintaining competitive pricing. Trust us as your partner in achieving the optical precision necessary for your success.Best Way To Optical Precision Machining Dominates Is The Best

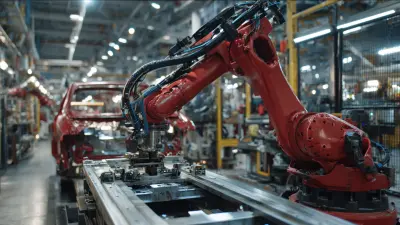

In the world of Optical Precision Machining, the quest for excellence is paramount. With advancements in technology and an increasing demand for precision components, mastering the art of machining is essential for companies aiming to lead in the global market. High-precision machining involves utilizing cutting-edge CNC machines, lathes, milling machines, and grinding machines to create components that meet the stringent requirements of various industries, including aerospace, medical, and telecommunications. By leveraging state-of-the-art equipment, manufacturers can achieve exceptional accuracy, ensuring that every part functions flawlessly in its final application. Effective Optical Precision Machining not only hinges on the technology employed but also on the skills and expertise of the workforce. A deep understanding of machining processes, materials, and tolerances is crucial in delivering high-quality products. Furthermore, employing rigorous quality control measures with tools like Coordinate Measuring Machines (CMM) and 2D image measuring instruments helps ensure that every piece produced meets specified standards. This combination of technology and skill positions companies to dominate the precision machining sector, offering reliable solutions to global buyers seeking exceptional quality and performance. As the demand for optical precision components continues to rise, leveraging modern machining techniques becomes increasingly important. Companies that invest in advanced manufacturing systems and focus on continuous improvement will find themselves at the forefront of the industry. For global procurement specialists, partnering with leading manufacturers not only offers access to high-quality precision parts but also promises a collaborative approach towards innovation and growth in various applications.

Best Way To Optical Precision Machining Dominates Is The Best

| Machining Process | Material Type | Precision (μm) | Typical Applications | Cost per Unit ($) |

|---|---|---|---|---|

| CNC Milling | Aluminium Alloy | 10 | Aerospace Components | 15.00 |

| Laser Cutting | Stainless Steel | 5 | Medical Instruments | 30.00 |

| EDM (Electrical Discharge Machining) | Titanium | 2 | High-precision Molds | 100.00 |

| Optical Grinding | Glass | 1 | Lenses and Mirrors | 50.00 |

| Polishing | Copper | 2 | Electrical Connectors | 25.00 |

Must-Know Tips For Optical Precision Machining Ahead of the Curve Guarantees Peak Performance

L

Liam Young

The quality of the product is remarkable. The after-sales team was friendly and really helped me understand its features.

15 June 2025

N

Noah Miller

Very happy with the purchase! The quality is excellent, and I appreciate the responsiveness of the support team.

28 May 2025

O

Oliver Scott

Excellent quality! The after-sales support was professional, ensuring I was informed and satisfied.

16 June 2025

O

Oliver Perez

Quality and professionalism at its best! The support team answered all my questions swiftly.

01 July 2025

E

Emma Young

This product is life-changing! The quality is top-tier, and so was the support provided post-purchase.

31 May 2025

D

David Long

Outstanding product! I was impressed by the quality and the expertise of their support staff.

04 June 2025