Top Supplier of High-Quality Optical Part Surfaces - Leading Manufacturer Solutions

At Kansd Precision Industry Co., Ltd., we understand the importance of **Optical Part Surface Quality** for your business. We specialize in supplying precision-engineered optical components that adhere to strict industry standards. Our focus on superior surface quality enhances the performance of your final products. With my extensive experience, I can help you choose the right optical parts tailored to your specific applications, ensuring optimal results. Partnering with trusted suppliers like us is crucial for advancing your projects with innovation and excellence in optical technology.

Must-Know Tips For Optical Part Surface Quality Outperforms the Competition Global Reach

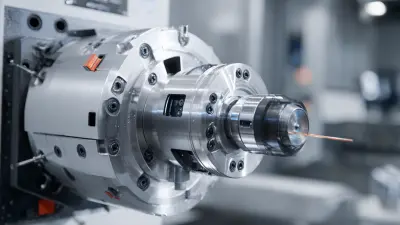

When it comes to the optical component industry, the surface quality of parts plays a crucial role in determining both performance and customer satisfaction. For global buyers seeking reliable suppliers, understanding the critical factors that contribute to superior surface quality is essential. Here are some must-know tips to ensure that your optical parts outshine the competition. First, Precision Manufacturing techniques such as CNC machining, lathing, and grinding are vital. These processes not only enhance the dimensional accuracy of components but also significantly improve surface finishes. Utilizing advanced equipment ensures uniform quality across large production runs. Pay attention to the type of machinery used by suppliers, as precision tools directly influence the final output's surface quality. Additionally, the application of medium-speed wire cutting can produce intricate designs with minimal burrs, leading to cleaner edges and improved aesthetics. Second, rigorous quality control measures are paramount. Implementing advanced inspection techniques like CMM (Coordinate Measuring Machine) and 2D image measurement systems allows for detailed surface analysis and assurance of compliance with strict industry standards. Global buyers should request information about the quality assurance processes employed by their suppliers to ensure that they meet expected surface quality benchmarks. By focusing on suppliers who prioritize these aspects, businesses can elevate their product offerings and enhance their competitive edge in the optical market.

Must-Know Tips For Optical Part Surface Quality Outperforms the Competition Global Reach

| Tip Number | Tip Description | Impact on Surface Quality | Global Application |

|---|---|---|---|

| 1 | Use Precision Polishing Techniques | Enhances clarity and reduces surface defects | Applicable in high-end optics globally |

| 2 | Implement Regular Quality Checks | Ensures consistent surface quality throughout production | Standard practice in all manufacturing sectors |

| 3 | Optimize Coating Processes | Improves durability and performance of optical parts | Used in Aerospace and medical industries |

| 4 | Train Staff on Surface Quality Standards | Reduces errors and increases output quality | Essential for teams worldwide |

| 5 | Invest in Advanced Measurement Tools | Provides accurate data for quality improvement | Critical for global manufacturers |

Best Way To Choose Optical Part Surface Quality Delivers Unmatched Quality Where Service Meets Innovation

W

William Jones

The quality is outstanding! The after-sales service was exceptional; the team was professional and proactive in solving my issues.

09 May 2025

H

Harper Lee

Fantastic purchase! The quality is stellar, and the after-sales staff provided me with invaluable support.

25 May 2025

J

Jackson Campbell

Exceptional quality product. The staff were knowledgeable and went above and beyond to assist me.

29 May 2025

B

Benjamin Scott

What a great investment! The product is high-quality, and the support team has been exceptionally professional.

04 July 2025

B

Benjamin Carter

Exceptional quality! The support team impressed me with their professionalism and willingness to assist.

01 July 2025

S

Sophia Martinez

What a great experience! The product is excellent, and the customer service team was professional and supportive.

12 June 2025