Top Optical Component Inspection Solutions from Leading Manufacturers & Factories

For Optical Component Inspection, partnering with dependable suppliers is essential for your business success. At Kansd Precision Industry Co., Ltd., we are recognized as a top manufacturer in this field. Our cutting-edge inspection solutions guarantee superior quality for your optical components, enabling you to uphold industry standards and enhance customer satisfaction.

Best Way To Optical Component Inspection Where Service Meets Innovation Pioneers in the Field

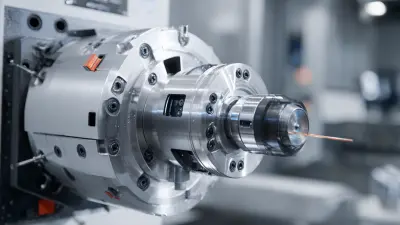

In the rapidly evolving landscape of Optical Component Inspection, precision and innovation go hand in hand. Companies today require solutions that not only meet rigorous quality standards but also embrace cutting-edge technologies. With advancements in CNC machining, lathing, milling, and grinding, manufacturers can now achieve unparalleled accuracy in their optical components. The synergy of these technologies ensures a meticulous inspection process that guarantees the performance and reliability of optical products. Moreover, the integration of advanced measurement systems, such as CMM and 2D image measuring instruments, plays a pivotal role in enhancing inspection accuracy. These tools enable manufacturers to conduct thorough assessments of optical components, ensuring they meet both industry standards and client specifications. By embracing innovation in the inspection process, companies can reduce waste, improve production efficiency, and ultimately deliver superior products to the global market. For procurement professionals seeking high-quality optical components, understanding these advancements is crucial. Partnering with manufacturers that prioritize both service and technological innovation not only fosters quality assurance but also enhances collaboration and customer satisfaction. As the demand for precise optical components grows, so does the importance of adopting best practices in inspection that reflect a commitment to excellence and continuous improvement in the industry.

| Inspection Method | Description | Accuracy (%) | Cost ($) | Time Required (mins) |

|---|---|---|---|---|

| Visual Inspection | Manual assessment using optical techniques. | 85 | 100 | 30 |

| Automated Optical Inspection (AOI) | Machine-driven inspections for quality control. | 95 | 200 | 15 |

| Laser Scanning | Precise measurements using laser technology. | 97 | 500 | 20 |

| Interferometry | High-precision measurements of optical surfaces. | 99 | 1000 | 25 |

| 3D Profilometry | Surface analysis using 3D imaging techniques. | 96 | 750 | 40 |

Key Methods For Optical Component Inspection Service Backed by Expertise Sets the Industry Standard

H

Harper Lee

Fantastic purchase! The quality is stellar, and the after-sales staff provided me with invaluable support.

25 May 2025

S

Sofia Robinson

An amazing product with great attention to quality. The after-sales support was equally impressive from start to finish.

25 June 2025

D

Daniel Harris

I really appreciate the quality of the product. The support team was prompt and knowledgeable, which made all the difference!

05 June 2025

B

Benjamin Carter

Exceptional quality! The support team impressed me with their professionalism and willingness to assist.

01 July 2025

M

Michael Allen

Excellent quality! The after-sales service was prompt, with an incredibly knowledgeable team.

01 July 2025

Z

Zoe Wright

Fantastic quality! The support staff were very helpful and professional throughout the process.

17 June 2025