01

Unveiling the Secrets Behind KANSD's Ultra - Precise Components for Semiconductor Industry

2025-08-06

The semiconductor industry is the beating heart of modern technology, driving innovation across a vast spectrum of sectors, from computing and telecommunications to consumer electronics. At the core of this industry's success lies the production of ultra - precise components, and KANSD has mastered the art of delivering these crucial elements with unparalleled accuracy.

The Semiconductor Industry's Need for Precision

Semiconductors are the building blocks of modern digital systems. Their components are incredibly small, often measured in nanometers, and the slightest imperfection can disrupt the flow of electrons, leading to device malfunctions. In a microprocessor, for example, billions of transistors need to be precisely manufactured and interconnected. Any deviation in their size, shape, or electrical properties can result in reduced performance, increased power consumption, or even complete failure of the chip. This extreme demand for precision is what sets the semiconductor industry apart and is the challenge that KANSD has embraced and overcome.

KANSD's Precision - Oriented Manufacturing Secrets

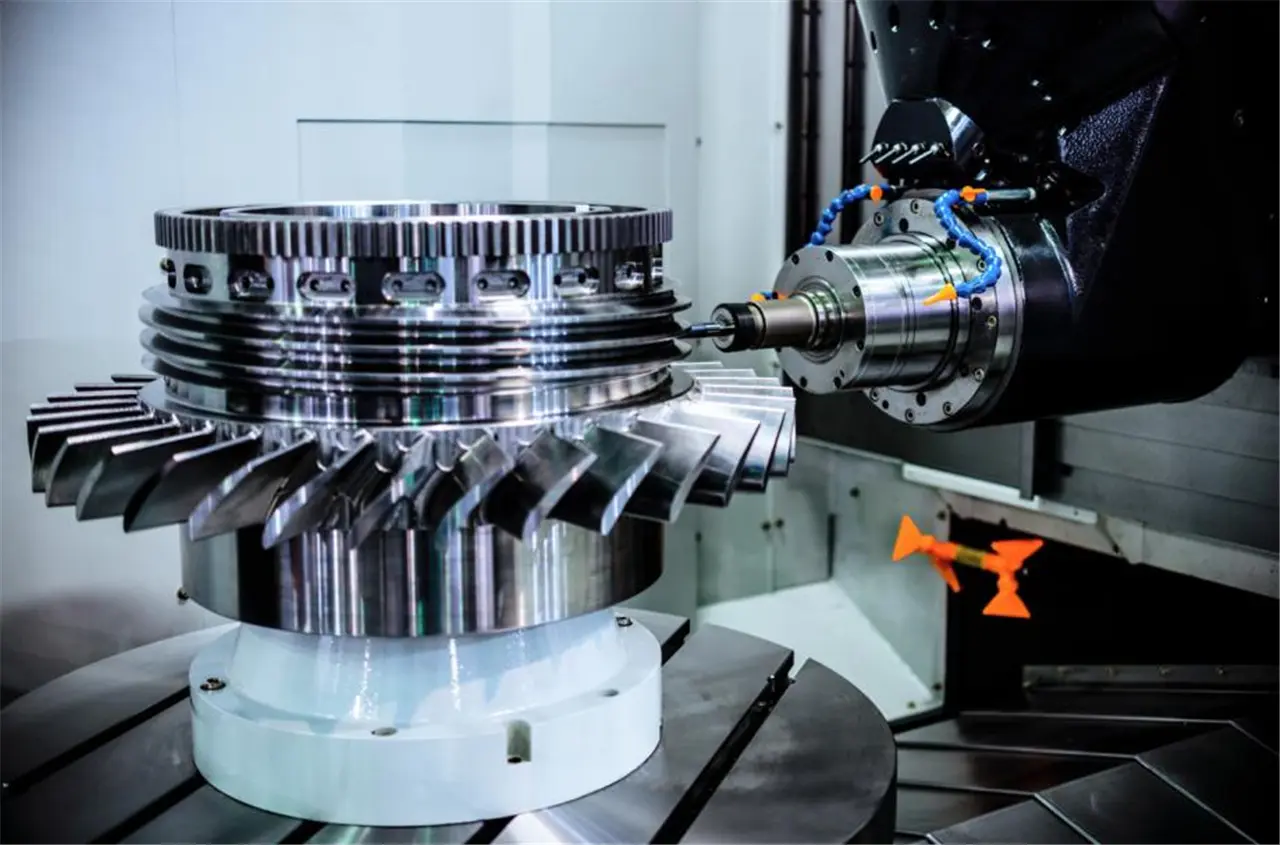

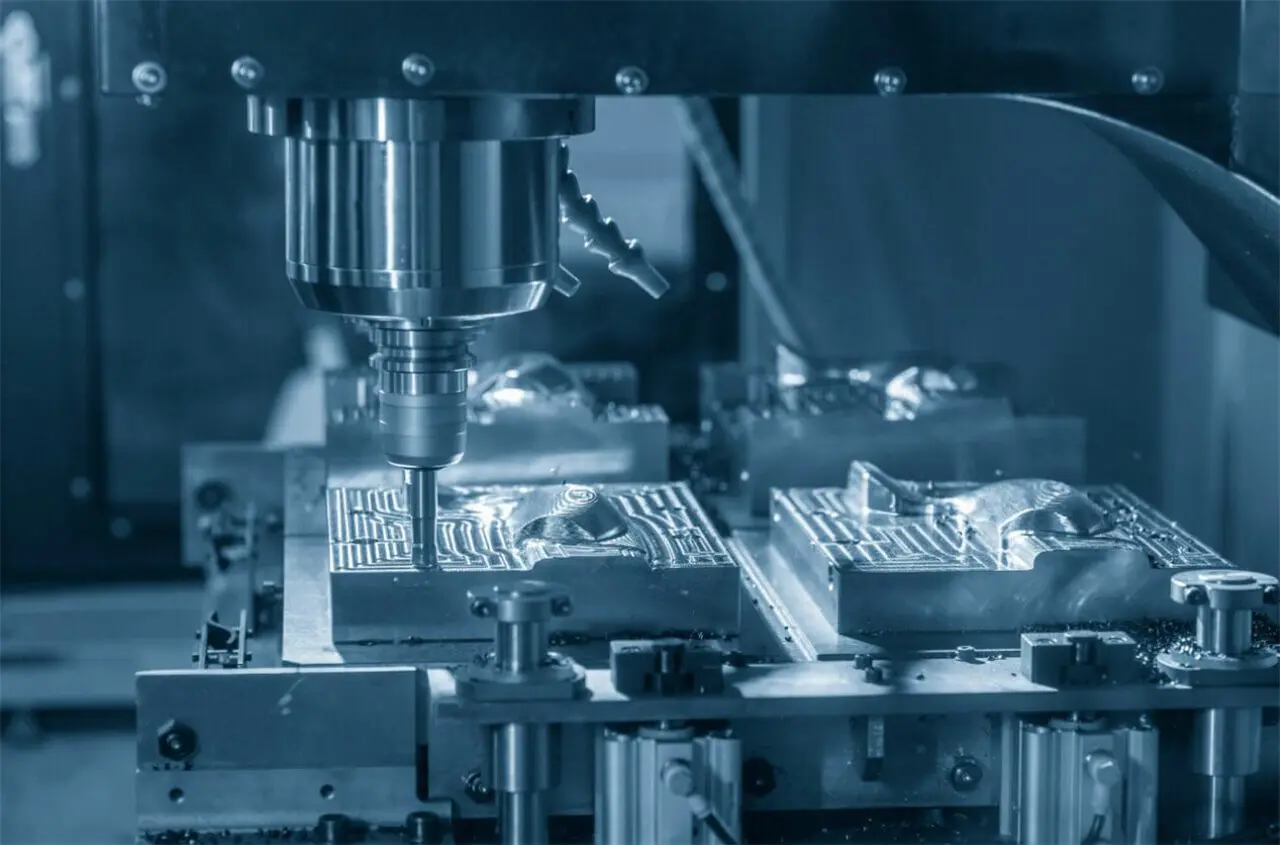

Cutting - Edge Manufacturing Technologies

KANSD invests heavily in the latest manufacturing technologies tailored to the semiconductor industry. Our advanced CNC machining centers are capable of achieving sub - micron precision, which is essential for creating semiconductor - related fixtures and tooling. These machines are programmed with highly sophisticated algorithms that can translate complex 3D designs into physical components with extraordinary accuracy. Additionally, we utilize state - of - the - art EDM (Electrical Discharge Machining) equipment, especially for creating intricate shapes and features in components made from hard - to - machine materials, such as tungsten carbide, which is commonly used in semiconductor manufacturing equipment.

Meticulous Process Control

The journey from raw material to a finished ultra - precise semiconductor component at KANSD is a highly regulated and controlled process. We start with carefully selected raw materials, ensuring their purity and consistency. Every step of the manufacturing process, from milling and grinding to heat treatment and surface finishing, is monitored in real - time. For instance, during the grinding process, we use advanced sensors to measure the material removal rate and adjust the grinding parameters accordingly, ensuring that the final dimensions of the component are within the tight tolerances required by the semiconductor industry. This level of process control is not only about achieving the right dimensions but also about ensuring the repeatability of the manufacturing process, so that every batch of components meets the same high - quality standards.

Expertise and Experience of the Team

Our team at KANSD is the driving force behind our success in semiconductor component manufacturing. Comprising engineers, technicians, and quality control experts, they bring a wealth of experience in precision manufacturing, with an average tenure of over 8 years. These professionals have in - depth knowledge of semiconductor manufacturing processes and are well - versed in the unique requirements of semiconductor - related components. They collaborate closely with our clients, understanding their specific needs and challenges. Whether it's developing a custom - designed wafer carrier with precise alignment features or a high - precision mask for photolithography, our team's expertise ensures that the final product is of the highest quality.

Impact on the Semiconductor Industry

Enabling High - Performance Semiconductor Devices

The ultra - precise components provided by KANSD play a pivotal role in the production of high - performance semiconductor devices. For example, our precision - made molds and fixtures are used in the semiconductor packaging process, ensuring that the delicate semiconductor chips are properly encapsulated and connected to the external circuitry. This precise packaging is crucial for maintaining the electrical and mechanical integrity of the device, enabling it to operate at high speeds and under extreme conditions. As a result, semiconductor manufacturers can produce chips with higher processing power, lower power consumption, and improved reliability, which are in high demand in the market.

Supporting Technological Advancements

In an industry that is constantly evolving, KANSD's capabilities are instrumental in supporting technological advancements. Our ability to manufacture ultra - precise components for emerging semiconductor technologies, such as 5G communication chips and artificial intelligence - enabled processors, is helping to push the boundaries of what is possible. By providing the necessary components with the required precision, we are enabling semiconductor companies to develop and commercialize innovative products more quickly, giving them a competitive edge in the global market.

Quality Assurance in Semiconductor Component Production

Quality is non - negotiable in the semiconductor industry, and KANSD takes every measure to ensure that our components meet the strictest quality standards. Our ISO 9001 and ISO 13485 certifications are a testament to our commitment to quality management. In addition to our regular in - process inspections, we conduct final product testing using advanced metrology equipment. Our coordinate measuring machines (CMMs) can measure the dimensions of components with sub - micron accuracy, while our 3D optical profilers are used to analyze the surface topography. This comprehensive quality assurance process ensures that the components leaving our facility are of the highest quality, minimizing the risk of defects and ensuring the smooth operation of semiconductor manufacturing processes.

In summary, KANSD's ultra - precise components are a result of a combination of cutting - edge technologies, meticulous process control, and a highly skilled team. Our contributions to the semiconductor industry are not only enabling the production of high - performance devices but also fueling technological innovation. As the semiconductor industry continues to grow and evolve, KANSD will remain dedicated to unveiling new secrets in precision manufacturing to meet the ever - increasing demands of this dynamic sector.