01

KANSD's Innovative Assembly Solutions: Driving Efficiency in Automotive Production

2025-08-06

In the fast - paced and highly competitive automotive industry, efficiency is the name of the game. Every step in the production process, from component manufacturing to final assembly, must be optimized to ensure high - quality vehicles are produced in a timely and cost - effective manner. KANSD has emerged as a key partner for automotive manufacturers, offering innovative assembly solutions that are revolutionizing production efficiency.

The Challenges in Automotive Assembly

Automotive assembly is a complex and multi - faceted process. It involves bringing together thousands of components, each with its own precise specifications. Ensuring that these components fit together perfectly, function as intended, and contribute to the overall performance and safety of the vehicle is no easy feat. Moreover, as automotive technology evolves, with the increasing integration of electric drivetrains, advanced driver - assistance systems (ADAS), and lightweight materials, the assembly process has become even more intricate. Manufacturers face the constant pressure to reduce production times, minimize errors, and enhance the overall quality of the final product.

KANSD's Innovative Assembly Solutions

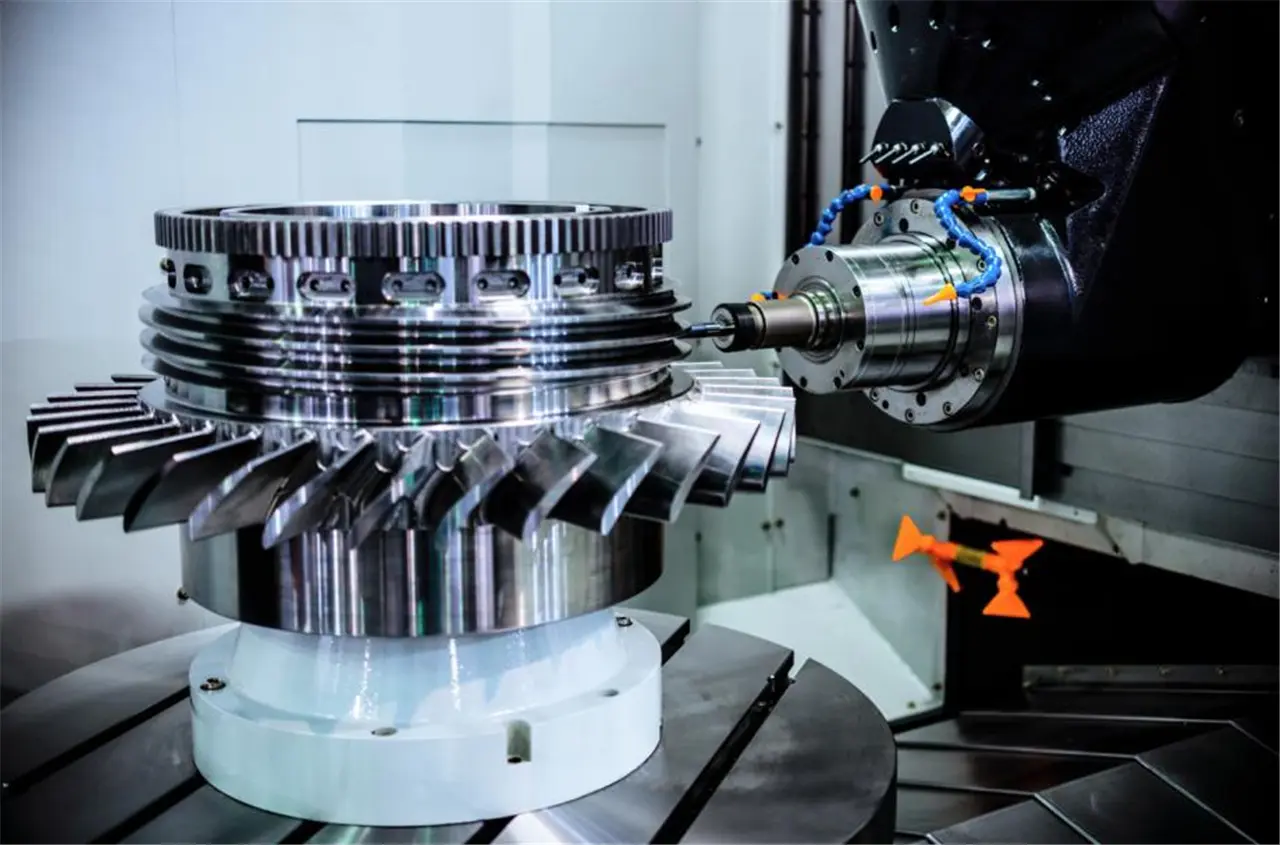

Custom - Designed Assembly Fixtures

One of KANSD's key offerings is the design and production of custom - designed assembly fixtures. These fixtures are tailored to the specific requirements of each automotive assembly task. For example, when assembling the engine block, our engineers create fixtures that hold the block in the optimal position, allowing for easy access to all the necessary attachment points. These fixtures are designed with precision, ensuring that components are aligned accurately every time. By using these custom fixtures, automotive manufacturers can significantly reduce the time spent on manual alignment and adjustment during the assembly process. This not only speeds up production but also improves the consistency and quality of the assembly, as each unit is assembled to the exact same high - standard.

Precision - Based Sub - Assembly Modules

KANSD also specializes in creating precision - based sub - assembly modules. Instead of sending individual components to the automotive assembly line, we pre - assemble groups of components into modules. For instance, we might create a complete dashboard sub - assembly, including the instrument cluster, air vents, and control panels. These sub - assemblies are manufactured with the highest level of precision at our facility. When they reach the automotive production line, they can be quickly and easily integrated into the vehicle. This approach streamlines the assembly process, reduces the number of individual component handling steps, and minimizes the risk of errors. It also allows for better quality control, as each sub - assembly can be thoroughly tested before being sent to the final assembly line.

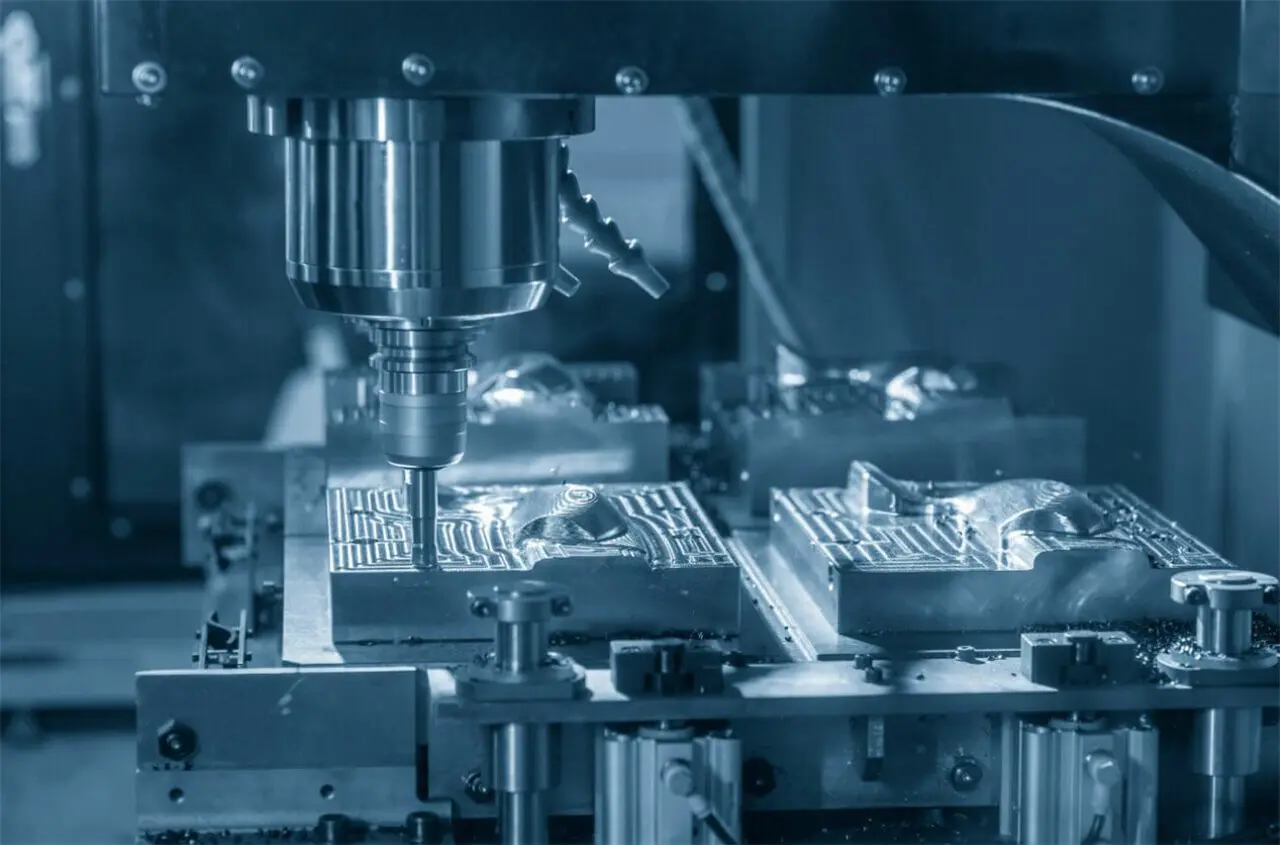

Advanced Assembly Process Optimization

Our team of experts at KANSD works closely with automotive manufacturers to optimize their entire assembly process. We analyze every step of the production line, from the flow of components to the sequence of assembly operations. By using advanced simulation software, we can model different scenarios and identify bottlenecks in the process. For example, we might discover that a particular assembly station is causing delays due to a complex hand - off between two workers. Based on these findings, we can suggest changes such as re - designing the workstation layout, adjusting the assembly sequence, or implementing new ergonomic tools. These optimizations lead to smoother production flow, reduced cycle times, and increased overall efficiency.

Impact on Automotive Production Efficiency

Reduced Assembly Time

The implementation of KANSD's innovative assembly solutions has led to a significant reduction in overall assembly time for automotive manufacturers. The use of custom - designed fixtures and pre - assembled sub - modules allows for faster component installation. For example, some of our clients have reported a 20 - 30% reduction in the time taken to assemble a complete vehicle. This reduction in assembly time not only increases the number of vehicles that can be produced in a given period but also enables manufacturers to respond more quickly to market demands.

Improved Quality and Reliability

By ensuring precise alignment and assembly of components, KANSD's solutions contribute to improved vehicle quality and reliability. The use of pre - assembled sub - modules, which are tested before integration, reduces the likelihood of defects in the final product. This results in fewer warranty claims and recalls, enhancing the reputation of automotive manufacturers in the market. Higher - quality vehicles also lead to increased customer satisfaction, which can translate into repeat business and brand loyalty.

Cost Savings

The increased efficiency and reduced error rates achieved through KANSD's assembly solutions also result in significant cost savings for automotive manufacturers. Shorter assembly times mean lower labor costs per vehicle. Additionally, fewer defects and recalls reduce the costs associated with post - production repairs and customer compensation. The overall cost savings can be reinvested in other areas of the business, such as research and development for new automotive technologies.