High-Quality Custom Machining Fixtures | Reliable Factory Solutions Supplier

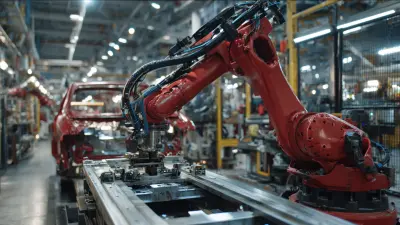

At Kansd Precision Industry Co., Ltd., we specialize in high-quality Machining Fixtures that enhance manufacturing processes with precision and reliability. Our fixtures are engineered to deliver accuracy and efficiency, addressing the needs of B2B buyers who seek durable solutions to optimize productivity and reduce downtime. With our experienced team and advanced technology, we create customized fixtures tailored to sectors such as automotive and aerospace. Partnering with us means choosing a manufacturer dedicated to honoring your time and investment, allowing you to elevate your machining capabilities.Must-Know Tips For Machining Fixtures Factory-Direct Excellence Supplies the World’s Top Brands

When it comes to sourcing machining fixtures, understanding the essentials can significantly enhance your procurement process. Factories that supply excellence directly to top brands often have advanced capabilities such as CNC machining, lathing, and grinding, ensuring they meet stringent quality demands. For global purchasers, identifying suppliers that utilize state-of-the-art machinery, including medium-speed wire cutting machines and CMM for precise measurement, is crucial. This level of technology allows for the production of intricate and high-Precision Components that are vital in today’s competitive landscape. Moreover, the assembly capabilities of a manufacturer can also play a pivotal role in the speed and efficiency of the supply chain. A robust assembly process, backed by quality assurance practices and efficient workflow, minimizes delays and enhances the end product’s reliability. As a global buyer, it’s important to choose factories that not only produce but also rigorously test their products through 2D image measurement instruments and other evaluation methods. This attention to detail translates into the quality that top brands demand, ensuring that the products meet industry standards. Finally, consider the versatility and customization options that a manufacturer offers. The ability to tailor machining fixtures to specific needs allows for better integration into production lines and helps improve operational efficiencies. Engage with suppliers who are willing to collaborate on bespoke solutions—this partnership can lead to innovative product developments, driving success in your business ventures. Choosing the right factory-direct supplier can be the key to unlocking excellence and achieving your business goals in the fast-evolving global market.

Must-Know Tips For Machining Fixtures Factory-Direct Excellence Supplies the World’s Top Brands

| Tip Number | Tip Description | Benefits | Application |

|---|---|---|---|

| 1 | Ensure Proper Alignment | Reduces machining errors | All types of machining processes |

| 2 | Choose the Right Material | Enhances durability | Fixture fabrication |

| 3 | Implement Routine Maintenance | Prevents unexpected downtimes | Machining equipment |

| 4 | Utilize CAD Software | Improves precision and design process | Designing fixtures |

| 5 | Train Your Staff | Enhances safety and efficiency | All manufacturing processes |

Step-by-Step Guide To Machining Fixtures Is The Best Stands Out

N

Noah Thomas

This product has proven to be both reliable and high-quality. The support from the staff really enhanced my experience.

10 May 2025

O

Owen Davis

Very pleased with this purchase! The quality is noticeable, and the staff were incredibly professional and helpful.

30 June 2025

V

Victoria Edwards

The quality is outstanding. The after-sales team was professional, making my experience a pleasure.

03 July 2025

J

James Turner

Incredible purchase! The quality has exceeded my expectations, and the support team was professional and responsive.

19 May 2025

O

Olivia Davis

This product exceeded my expectations. The after-sales team provided an excellent service with their professional attitude.

15 May 2025

A

Amelia Harris

Impressive purchase! The product is high quality, complemented by an excellent support team.

22 May 2025