Custom Machining Services with 0.002mm Precision - Top Manufacturer & Supplier

Achieving precision machining with an accuracy of 0.002mm is essential for your projects. As a dedicated manufacturing partner, I deliver high-quality components that adhere to the stringent standards across various industries. My factory utilizes advanced technology and experienced craftsmen to ensure each part is meticulously crafted. At Kansd Precision Industry Co., Ltd., my commitment to excellence and customer satisfaction stands at the forefront. Whether you require prototypes or large-scale production, I provide tailored solutions to meet your specific needs. Collaborating with me guarantees reliable service and products that bolster your operations, helping you elevate your projects to new heights.

Why Invest In Machining Accuracy 0.002mm Products Application

In today’s competitive manufacturing landscape, precision is not just an advantage; it’s a necessity. Investing in machining accuracy, particularly with a tolerance of 0.002mm, can significantly enhance product quality and reliability. Such precision is critical for industries ranging from aerospace to medical devices, where even the slightest deviation can lead to costly failures or safety hazards. By choosing products that adhere to this high standard of accuracy, companies can ensure optimal performance, reduce material wastage, and minimize rework, ultimately leading to higher profitability. The capabilities offered by advanced machining technologies are vital for achieving such precision. With state-of-the-art CNC machines, lathes, and grinding machines, manufacturers can produce components that meet the exacting requirements of their clients. Coupled with precise inspection tools like CMM and 2D image measuring instruments, manufacturers can guarantee that each component meets specified tolerances before it leaves the production line. This meticulous attention to detail not only enhances product quality but also strengthens customer trust and satisfaction, paving the way for long-term partnerships. Furthermore, investing in High-Precision Machining aligns with global trends toward customization and adaptability in manufacturing. As industries demand more specialized and complex components, the ability to deliver precisely made parts quickly becomes a crucial differentiator. Companies that prioritize machining accuracy are well-positioned to meet these evolving market needs and maintain a competitive edge on a global scale. Ultimately, the decision to invest in high-accuracy products translates to improved product performance, greater operational efficiency, and enhanced market opportunities.

Why Invest In Machining Accuracy 0.002mm Products Application

| Application Area | Machining Accuracy (mm) | Benefits | Industry Examples |

|---|---|---|---|

| Aerospace | 0.002 | Improved safety and performance | Jet engines, aircraft structures |

| Medical Devices | 0.002 | Enhanced patient safety and equipment reliability | Surgical instruments, diagnostic machines |

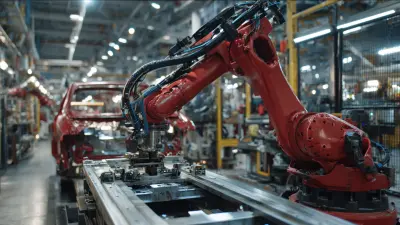

| Automotive | 0.002 | Better fuel efficiency and emissions control | Engine components, transmission systems |

| Electronics | 0.002 | Higher performance and miniaturization | Semiconductors, circuit boards |

| Defense | 0.002 | Increased reliability and durability | Weapons systems, surveillance equipment |

Must-Know Tips For Machining Accuracy 0.002mm Outperforms the Competition Exceeds Industry Benchmarks

M

Michael Sampson

The product quality exceeded my expectations. The support team was incredibly responsive and professional, making the entire experience seamless.

25 June 2025

R

Rachel Adams

This product has significantly improved our workflow. The professionalism of the support staff really made a difference in our experience.

14 June 2025

Z

Zoe Powell

What an incredible product! The after-sales service team was quick, thorough, and very professional in their approach.

12 June 2025

S

Sophia Nelson

Great product quality! The after-sales service was second to none, with a staff that truly cares.

01 July 2025

J

Jackson Taylor

The quality is outstanding! I was very pleased with how professional the support team was during my inquiry.

07 June 2025

G

Grace Hernandez

What a fantastic product! The thoughtful support from their team made my experience even better.

10 May 2025