Top Precision Lathe Machining Manufacturers & Factories for High-Quality Parts

At Kansd Precision Industry Co., Ltd., we understand that high-quality lathe machining is crucial for your precision engineering projects. As a trusted manufacturer and supplier, we deliver outstanding results tailored to your specific requirements. Our skilled technicians and advanced machinery work in unison to produce reliable components designed to endure even the most demanding conditions. We prioritize timely delivery and exceptional customer service, ensuring that your needs are met throughout the entire process, from initial inquiry to final product delivery. Whether you require custom parts or standard components, our Lathe Machining Services are made to provide the precision and durability your business deserves. Partner with us to experience the impact of quality and reliability on your operations. Together, we can create exceptional results.Practical Strategies for Lathe Machining Factory in 2025

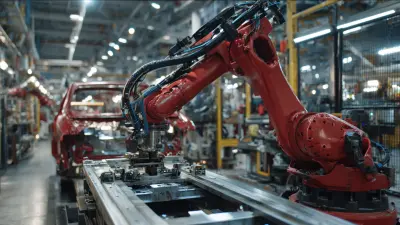

As we look towards 2025, lathe machining factories must adopt practical strategies to stay competitive in the global Precision Manufacturing market. One of the key strategies is the integration of advanced CNC technologies that enhance efficiency and precision. Leveraging CNC machines allows for higher accuracy and faster production rates, which are crucial in meeting the increasing demand for customized components. Factories should consider implementing intelligent automation to streamline operations and reduce lead times, enabling them to respond swiftly to market changes. Another vital aspect is investing in workforce training and development. Skilled operators who can effectively utilize state-of-the-art machinery are indispensable for maintaining high-quality standards. Regular training programs can help employees stay abreast of the latest machining techniques and technology advancements, thereby enhancing overall productivity. Additionally, fostering a culture of innovation within the workforce will encourage creative problem-solving, essential for overcoming manufacturing challenges. Lastly, focusing on sustainability can set lathe machining companies apart in a crowded marketplace. By adopting eco-friendly practices, such as minimizing waste and utilizing energy-efficient machines, factories can appeal to environmentally conscious buyers. Implementing a robust supply chain management strategy that prioritizes sustainability will not only enhance corporate responsibility but also attract global buyers looking for suppliers committed to eco-friendly practices. Embracing these strategies will position lathe machining factories for success in the evolving landscape of Precision Manufacturing.

Practical Strategies for Lathe Machining Factory in 2025

| Strategy | Description | Benefits | Implementation Timeline |

|---|---|---|---|

| Automation Integration | Incorporating automated lathes and robotics for repetitive tasks. | Increased efficiency and reduced labor costs. | Q1 2025 - Q3 2025 |

| Employee Training | Providing advanced training on new technologies and machinery. | Enhanced skill sets leading to higher quality outputs. | Ongoing throughout 2025 |

| Sustainability Practices | Implementing eco-friendly processes and materials. | Improved public image and potential cost savings. | Q2 2025 - Q4 2025 |

| IoT Monitoring | Utilizing IoT devices for real-time monitoring of machine conditions. | Preventive maintenance and reduced downtime. | Q1 2025 - Q2 2025 |

| Quality Control Systems | Implementing advanced QA methodologies and tools. | Higher product quality and customer satisfaction. | Q3 2025 - Q4 2025 |

How-To Guide Lathe Machining Exceeds Industry Benchmarks From Concept to Delivery

L

Liam Young

The quality of the product is remarkable. The after-sales team was friendly and really helped me understand its features.

15 June 2025

W

William Shaw

This product is well-made and delivers excellent results. The follow-up service was conducted by highly knowledgeable staff.

23 May 2025

V

Victoria Edwards

The quality is outstanding. The after-sales team was professional, making my experience a pleasure.

03 July 2025

M

Mia White

I love the product! Its quality stands out, and the after-sales service was efficient and friendly.

24 May 2025

M

Michael Allen

Excellent quality! The after-sales service was prompt, with an incredibly knowledgeable team.

01 July 2025

I

Isabella White

What an excellent find! The quality is exceptional and the after-sales service team was incredibly professional and helpful.

27 June 2025