Optimizing Fixture Manufacturing Lead Times with Quality Suppliers and Factories

In the realm of Fixture Manufacturing Lead Time, Kansd Precision Industry Co., Ltd. prioritizes your time and investment. Our partnerships with leading suppliers and factories enable us to optimize lead times while upholding the highest standards of quality. Our skilled team is committed to transparency, ensuring you stay informed about your order's progress. When you choose to work with us, you’re selecting reliability and excellence in fixture manufacturing. Let us enhance your projects efficiently, delivering the top-notch fixtures you expect, with a focus on your satisfaction.

10 Essential Tips For Fixture Manufacturing Lead Time Trusted by Pros Leads the Global Market

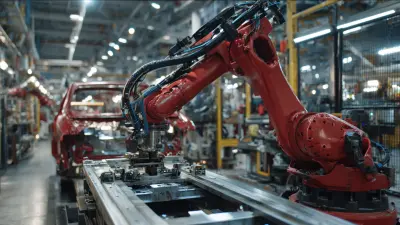

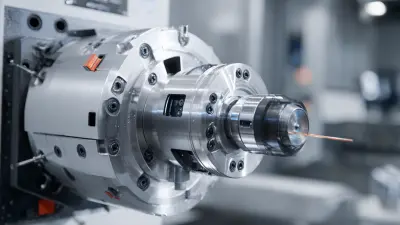

In the world of fixture manufacturing, lead time is a critical aspect that significantly influences production efficiency and customer satisfaction. Achieving optimal lead times requires a combination of advanced technology and skilled craftsmanship. Utilizing state-of-the-art equipment such as CNC machines, lathes, and precision measuring instruments allows manufacturers to streamline their processes, reduce errors, and improve overall output quality. This not only accelerates production but also enhances the ability to meet tight deadlines, which is essential for maintaining a competitive edge in the global market. Moreover, communication and collaboration between buyers and manufacturers play a vital role in ensuring smooth operations. Establishing clear expectations regarding timelines, order specifications, and potential challenges can lead to better planning and resource allocation. This proactive approach can help in managing lead times effectively, minimizing delays caused by unforeseen circumstances. Additionally, continuous improvement practices within the manufacturing process, informed by feedback and performance data, enable companies to adapt swiftly to changing market demands and enhance their reliability as suppliers. For global buyers, selecting a fixture manufacturer that prioritizes lead time management can result in significant cost savings and improved project outcomes. By leveraging the latest technologies and fostering strong relationships with suppliers, companies can confidently navigate the complexities of production, ensuring timely delivery and high-quality results that meet international standards. Investing time in understanding the capabilities and practices of potential manufacturing partners is essential for making informed procurement decisions that align with business goals.

10 Essential Tips For Fixture Manufacturing Lead Time Trusted by Pros Leads the Global Market

| Tip No. | Tip | Description | Expected Impact (Days) |

|---|---|---|---|

| 1 | Clear Communication | Establish clear communication channels with clients. | 2 |

| 2 | Use Advanced Technology | Incorporate CAD/CAM software for design accuracy. | 3 |

| 3 | Optimize Inventory | Maintain optimal inventory levels to reduce delays. | 2 |

| 4 | Efficient Scheduling | Create a detailed production schedule for better flow. | 4 |

| 5 | Regular Training | Provide ongoing training for staff to improve skills. | 1 |

| 6 | Supplier Relationships | Build and maintain strong relationships with suppliers. | 3 |

| 7 | Quality Control | Implement strict quality control measures at each stage. | 2 |

| 8 | Feedback Loop | Establish a feedback loop with customers after projects. | 1 |

| 9 | Use Data Analytics | Utilize data analytics for process improvement. | 2 |

| 10 | Risk Management | Develop a robust risk management strategy. | 5 |

Key Steps to Choosing Fixture Manufacturing Lead Time Products Factory

E

Emma Smith

Quality products coupled with outstanding customer support. The professional approach of the staff left a lasting impression on me.

03 July 2025

I

Isabella Lewis

Top-notch quality! The after-sales experience was made smooth by a team that genuinely knows their products.

25 June 2025

Z

Zoe Powell

What an incredible product! The after-sales service team was quick, thorough, and very professional in their approach.

12 June 2025

E

Eli Bell

What a fantastic product! The level of support from the team was impressive and made my experience effortless.

30 June 2025

S

Sophia Parker

Amazing quality! The after-sales support team went above and beyond, ensuring all my needs were met.

05 June 2025

L

Liam King

Extremely satisfied with the product! The after-sales team was responsive and knowledgeable, providing great assistance.

18 June 2025