Top Manufacturers for High-Quality CNC Turning Surface Finishes Online

For top-notch Cnc Turning Surface Finish, quality and reliability in suppliers are key. With extensive industry experience, I emphasize the vital role of CNC turning in achieving precise results for your projects. At Kansd Precision Industry Co., Ltd., we are dedicated to customer satisfaction and uphold high manufacturing standards. Our advanced techniques and premier materials guarantee finishes tailored to your specifications. Whether you require prototypes or large-scale production, our modern facilities deliver consistent outcomes. Effective communication and timely delivery are fundamental to our partnerships. Partner with us to enhance your production capabilities and achieve exceptional surface finishes for your components. Quality is our priority, and we are committed to providing the best solutions in CNC turning.

Discovering Cnc Turning Surface Finish Global Reach Sets the Industry Standard

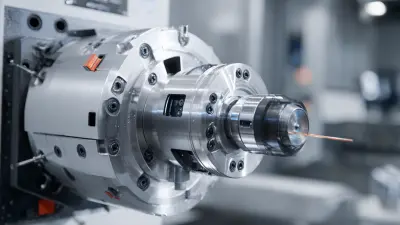

In the ever-evolving landscape of Precision Manufacturing, CNC turning has emerged as a pivotal technology that sets the standard for surface finishes globally. With the increasing demand for high-quality components across various industries, manufacturers are challenged to enhance their production capabilities while adhering to stringent quality standards. The advent of advanced CNC machines enables the creation of intricate designs with impeccable precision, ensuring that every product meets the exact specifications of global procurement partners. The versatility of CNC turning not only facilitates complex geometrical shapes but also offers superior surface finishes that elevate the performance of end products. Industries ranging from automotive to aerospace have recognized the importance of these capabilities in achieving optimal operational efficiency. By leveraging cutting-edge machinery such as lathes, milling machines, and grinding machines, manufacturers can ensure a consistent finish that not only enhances aesthetic appeal but also improves functionality and durability. As businesses strive to meet global market demands, understanding the role of Precision Manufacturing in achieving superior surface finishes becomes critical. Collaborating with proficient suppliers who utilize state-of-the-art equipment and adhere to best practices in quality control is essential for securing a competitive edge in both local and international markets. Embracing this technology not only streamlines production processes but also builds trust with procurement partners, fostering long-term business relationships in an increasingly interconnected world.

Discovering Cnc Turning Surface Finish Global Reach Sets the Industry Standard

| Region | Average Surface Finish (Ra µm) | Commonly Used Materials | Standard CNC Technology | Market Share (%) |

|---|---|---|---|---|

| North America | 0.4 | Aluminum, Stainless Steel | CNC Lathe, 5-Axis CNC | 35 |

| Europe | 0.3 | Copper, Brass | CNC Milling, CNC Turning | 30 |

| Asia-Pacific | 0.5 | Steel, Titanium | CNC Machining, Multi-Tasking | 25 |

| Latin America | 0.6 | Plastic, Aluminum | CNC Router, Turn-Mill | 5 |

| Middle East & Africa | 0.7 | Stainless Steel, Copper | CNC Lathe, Fiber Laser Cutting | 5 |

Where the Value Lies Cnc Turning Surface Finish Dominates Industry Leaders

S

Sophia Nelson

The attention to detail in the product is impressive. The post-purchase service was handled by a highly skilled team who really know their stuff.

26 May 2025

E

Emma Reed

The product quality is fantastic. The after-sales service was impressive, with knowledgeable staff always ready to help.

17 May 2025

W

William Shaw

This product is well-made and delivers excellent results. The follow-up service was conducted by highly knowledgeable staff.

23 May 2025

S

Sophia Rivera

Quality was excellent! The after-sales service team provided timely and professional assistance.

31 May 2025

E

Emma Hernandez

Wonderful product! The after-sales team was efficient and very knowledgeable, providing the support I needed.

27 May 2025

L

Liam King

Extremely satisfied with the product! The after-sales team was responsive and knowledgeable, providing great assistance.

18 June 2025