CNC Machining Challenges and Solutions: Top Suppliers & Manufacturers Revealed

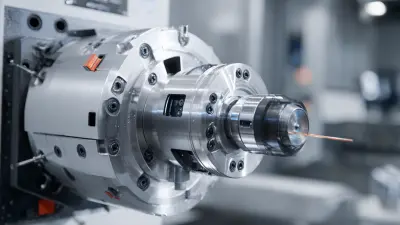

CNC machining presents its own set of challenges, such as precision matters and material variances. My approach involves prioritizing effective solutions tailored to the specific requirements of each custom project. By collaborating closely with factories and suppliers, I guarantee that every component is produced with the utmost precision, minimizing the likelihood of errors and delays.

Must-Choose Reasons Cnc Machining Problems And Solutions Your Trusted OEM Partner Factory-Direct Excellence

In the fast-paced world of Precision Manufacturing, CNC machining plays a pivotal role in delivering high-quality components for various industries. However, challenges often arise during the machining process, including material inconsistencies, tooling wear, and machine calibration issues. To mitigate these problems, partnering with a reliable OEM can significantly enhance the production process. A committed partner ensures that advanced CNC machines, lathes, and grinding machines are meticulously maintained and calibrated, thereby minimizing downtime and ensuring top-tier precision. Moreover, an OEM partner equipped with modern inspection tools, such as CMM and 2D image measuring instruments, can provide comprehensive quality assurance. These technologies facilitate real-time monitoring and assessment of the machining process, ensuring that every component meets stringent specifications and industry standards. Additionally, leveraging a partner's expertise in assembly can streamline operations, reduce lead times, and help navigate complex manufacturing challenges. Ultimately, choosing the right OEM partner is more than just a business decision; it’s a strategic move that can lead to improved efficiency and cost-effectiveness in production. By addressing the common CNC machining problems with innovative solutions, businesses can stay competitive in an ever-evolving market landscape.

Must-Choose Reasons Cnc Machining Problems And Solutions Your Trusted OEM Partner Factory-Direct Excellence

| Problem | Impact | Solution | Prevention |

|---|---|---|---|

| Tool Wear | Increased production costs and reduced quality | Regular tool inspection and timely replacement | Implementing a tool management system |

| Dimensional Accuracy | Product rejection and customer dissatisfaction | Calibrating machines frequently | Routine machine maintenance and checks |

| Surface Finish Issues | Affects product aesthetics and function | Using appropriate cutting tools and parameters | Training operators on finishing techniques |

| Overheating | Can lead to thermal distortion and poor finishes | Optimizing cutting speeds and feeds | Utilizing proper coolant and lubrication |

| Chip Removal | Can cause tool damage and surface imperfections | Regular chip removal during machining | Designing parts that facilitate efficient chip flow |

Best Ways To Cnc Machining Problems And Solutions Exceeds Industry Benchmarks Winning in 2025

R

Rachel Adams

This product has significantly improved our workflow. The professionalism of the support staff really made a difference in our experience.

14 June 2025

B

Benjamin Scott

What a great investment! The product is high-quality, and the support team has been exceptionally professional.

04 July 2025

G

Grace Collins

Excellent craftsmanship! The after-sales service team was very responsive and knowledgeable.

15 May 2025

V

Victoria Edwards

The quality is outstanding. The after-sales team was professional, making my experience a pleasure.

03 July 2025

O

Olivia Davis

This product exceeded my expectations. The after-sales team provided an excellent service with their professional attitude.

15 May 2025

M

Mia White

I love the product! Its quality stands out, and the after-sales service was efficient and friendly.

24 May 2025