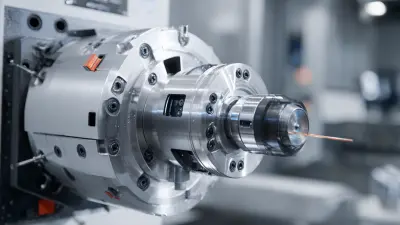

Top CNC Machine Maintenance Tips: Best Solutions from Leading Manufacturers

Ensuring optimal performance and longevity for your CNC machines is essential in any manufacturing environment. At Kansd Precision Industry Co., Ltd., we recognize the specific challenges faced by businesses and provide tailored solutions that boost efficiency while reducing downtime. With our dedicated team, you can trust in our commitment to quality and excellence. Together, we can enhance the value of your CNC operations and ensure they run smoothly.

Best Way To Cnc Machine Maintenance From Concept to Delivery Supplies the World’s Top Brands

Maintaining CNC machines is critical for ensuring precision and longevity in the manufacturing process. A well-structured maintenance program can significantly reduce downtime, increase production efficiency, and ultimately enhance product quality. From regular routine checks to more in-depth inspections, understanding the best practices for Cnc Machine Maintenance is vital for businesses looking to optimize their operations. Key components of an effective maintenance strategy include daily cleanings, weekly lubrication, and periodic calibration, all tailored to your specific machinery and operational demands. As you consider Cnc Machine Maintenance, it is important to leverage advanced technology and skilled professionals. Employing high-precision tools and measurement instruments ensures that maintenance tasks are performed with accuracy and consistency. Regular training for personnel on the latest maintenance techniques can also help mitigate unexpected breakdowns and extend the life of your machinery. By prioritizing maintenance, manufacturers not only protect their investments but also position themselves to meet the evolving needs of clients globally. In conclusion, effective maintenance of CNC machines is not just a reactive measure but a proactive approach that supports production goals and customer satisfaction. Companies committed to excellence understand that maintaining their equipment is a crucial step in delivering high-quality products. By investing in comprehensive maintenance protocols, manufacturers can better serve their clients and stay competitive in the dynamic global marketplace.

Best Way To Cnc Machine Maintenance From Concept to Delivery Supplies the World’s Top Brands

| Maintenance Type | Frequency | Tools Required | Estimated Time (Hours) | Cost Estimation ($) |

|---|---|---|---|---|

| Lubrication | Monthly | Lubricant, Grease Gun | 0.5 | 50 |

| Filter Replacement | Quarterly | Replacement Filters, Wrench | 1 | 200 |

| Calibration | Biannually | Calibration Tools | 2 | 300 |

| Software Update | Annually | Computer, USB Drive | 0.5 | 150 |

| Visual Inspection | Monthly | Inspection Tools | 0.25 | 20 |

How To Identify Cnc Machine Maintenance Manufacturer Stands Out

M

Michael Sampson

The product quality exceeded my expectations. The support team was incredibly responsive and professional, making the entire experience seamless.

25 June 2025

S

Sophia Nelson

The attention to detail in the product is impressive. The post-purchase service was handled by a highly skilled team who really know their stuff.

26 May 2025

A

Ava Baker

Incredible product quality. The support team was quick, friendly, and professional, ensuring all my questions were addressed.

26 May 2025

O

Oliver King

Very impressed with the overall product quality. The professionalism of the support team made the experience so much better.

11 May 2025

N

Nathan Carter

The product quality truly impressed me. The staff were remarkable in their follow-up and support.

01 July 2025

A

Amelia Harris

Impressive purchase! The product is high quality, complemented by an excellent support team.

22 May 2025