Custom CNC Aerospace Machining Services from Top Manufacturers & Suppliers

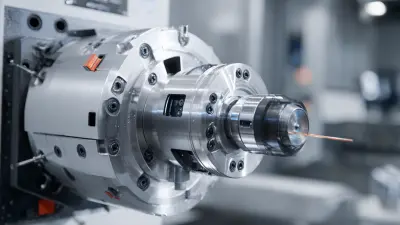

When it comes to Cnc Aerospace Machining, precision and reliability are paramount. At Kansd Precision Industry Co., Ltd., we specialize in providing top-quality CNC machining services tailored to meet rigorous aerospace standards. Our advanced technology and skilled team ensure that every component is constructed with meticulous attention to detail. Whether it’s intricate aircraft parts or components for space exploration, we utilize cutting-edge machining techniques and high-quality materials, ensuring performance in the most demanding conditions. Partnering with us offers not only superior products but also expert support throughout your aerospace projects. Together, we can elevate your endeavors with our exceptional CNC machining solutions.

Advantages Explained Cnc Aerospace Machining Trusted by Pros Supplier

In the aerospace industry, precision and reliability are paramount. Cnc Aerospace Machining has emerged as a trusted solution among professionals, offering several advantages that position it as the preferred choice for manufacturers and suppliers. One of the key benefits is the ability to achieve high levels of accuracy in complex geometries. With advanced CNC technologies, manufacturers can create intricate components that meet stringent industry standards, ensuring optimal performance and safety in aerospace applications. Moreover, CNC machining contributes to enhanced efficiency and reduced lead times. Automated processes minimize manual intervention, resulting in quicker production cycles and lower operational costs. This efficiency not only meets the demands of tight project timelines but also allows for greater flexibility in handling varying order sizes. Furthermore, the capability to produce consistent results batch after batch ensures that suppliers can maintain the quality and reliability that aerospace manufacturers require. Lastly, CNC machining enables manufacturers to work with a diverse array of materials, from high-strength alloys to lightweight composites. This adaptability is crucial in the aerospace sector, where material properties can significantly influence the performance and durability of components. By leveraging modern CNC technologies, companies can innovate and push the boundaries of aerospace design, ultimately contributing to advancements in aviation and space exploration.

Advantages Explained: CNC Aerospace Machining Trusted by Pros Supplier

| Advantage | Description | Industry Applications | Material Compatibility |

|---|---|---|---|

| Precision Manufacturing | CNC machining offers high precision for critical Aerospace parts. | Aerospace, Defense | Aluminum, Titanium, Composites |

| Reduced Lead Times | High-speed CNC machining allows for faster production cycles. | Commercial Aviation, Space | Steel, Aluminium Alloys |

| Cost Efficiency | Lower manufacturing costs due to reduced waste and labor. | Aeronautics, UAVs | Titanium, Plastics |

| Design Flexibility | Ability to create complex geometries and custom designs. | Spacecraft, Drones | Composites, High-strength Alloys |

| Quality Control | Highly controlled manufacturing processes ensure part quality. | Military Aviation, Satellite | Aluminium, Titanium |

Don't Miss These Cnc Aerospace Machining Sets the Industry Standard Manufacturer

E

Emma Johnson

The quality is exceptional and worth every penny. The after-sales team was attentive and knowledgeable, ensuring I was fully satisfied.

04 June 2025

O

Olivia Martinez

What an excellent product! The quality speaks for itself, and the customer service team was incredibly helpful, making the process smooth.

26 May 2025

I

Isabella Lewis

Top-notch quality! The after-sales experience was made smooth by a team that genuinely knows their products.

25 June 2025

L

Liam Young

The quality of the product is remarkable. The after-sales team was friendly and really helped me understand its features.

15 June 2025

O

Oliver King

Very impressed with the overall product quality. The professionalism of the support team made the experience so much better.

11 May 2025

S

Sophia Parker

Amazing quality! The after-sales support team went above and beyond, ensuring all my needs were met.

05 June 2025