Top Manufacturers & Suppliers of High-Precision Close-Tolerance Components

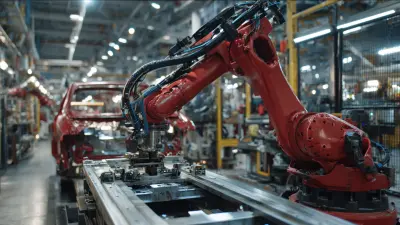

When high-quality Close-Tolerance Components are essential, reliability and precision become indispensable. As a dedicated manufacturer, we provide components that adhere to the highest industry standards. Utilizing advanced technology and expert craftsmanship, each piece is engineered for exceptional performance. Partnering with Kansd Precision Industry Co., Ltd. ensures that our products are tailored to meet your specific requirements, whether in aerospace, automotive, or other rigorous sectors. We emphasize quality control at every stage of production, guaranteeing that our Close-Tolerance Components will perform reliably under pressure. Selecting the right supplier is crucial, and we offer the quality and dependability you need. Let's work together to elevate your projects with our precision-engineered solutions built to last. Contact us today to find out how we can support your business objectives!Top 3 Close-Tolerance Components in 2025 Supplies the World’s Top Brands

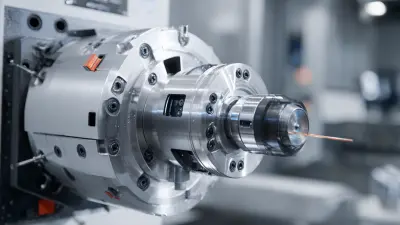

As precision manufacturing continues to evolve, the need for Close-Tolerance Components has become critical for industries ranging from aerospace to electronics. In 2025, the top three Close-Tolerance Components leading the market will be essential in meeting the intricate requirements of global brands. These components not only enhance performance but also ensure reliability in applications where precision is paramount. Firstly, advanced CNC-machined parts will take center stage. With their ability to produce complex shapes with unparalleled accuracy, these components are indispensable for companies that demand tight tolerances. The use of state-of-the-art lathes and milling machines, combined with precision assembly techniques, will facilitate the creation of parts that meet rigorous specifications and enhance product longevity. Secondly, custom-made grinding components will support the pursuit of excellence in manufacturing. The grinding process allows for surface finishes and dimensional tolerances that are crucial for certain applications. Companies will increasingly rely on these components to ensure seamless integration within their systems, reducing downtime and improving overall efficiency. Finally, medium-speed wire cutting machines will play a pivotal role in producing intricate designs with minimal material waste. This method is particularly advantageous for businesses looking for both precision and cost-effectiveness in their sourcing strategies. In summary, the demand for Close-Tolerance Components will continue to shape the landscape of precision manufacturing. Global brands must prioritize these advanced components to maintain their competitive edge and ensure the reliability of their products. Adaptability and precision in sourcing will be vital as industries evolve to meet the challenges of the future.

Top 3 Close-Tolerance Components in 2025 Supplies the World’s Top Brands

| Component Type | Material | Tolerance Level (mm) | Application | Annual Production (units) |

|---|---|---|---|---|

| Precision Gears | Steel | ±0.01 | Automotive Transmissions | 2,500,000 |

| CNC Machined Components | Aluminum | ±0.005 | Medical Devices | 1,200,000 |

| Housings | Titanium | ±0.002 | Aerospace | 750,000 |

Quick Tips To Close-Tolerance Components Global Reach Manufacturers You Can Rely On

G

Grace Collins

Excellent craftsmanship! The after-sales service team was very responsive and knowledgeable.

15 May 2025

V

Victoria Edwards

The quality is outstanding. The after-sales team was professional, making my experience a pleasure.

03 July 2025

M

Maya Lee

Great product quality and an even better after-sales experience. The staff handled everything with such care!

24 June 2025

J

James Turner

Incredible purchase! The quality has exceeded my expectations, and the support team was professional and responsive.

19 May 2025

L

Liam King

Extremely satisfied with the product! The after-sales team was responsive and knowledgeable, providing great assistance.

18 June 2025

G

Grace Torres

I am very pleased with my choice. The quality is excellent, and the support staff is ever so professional.

23 May 2025