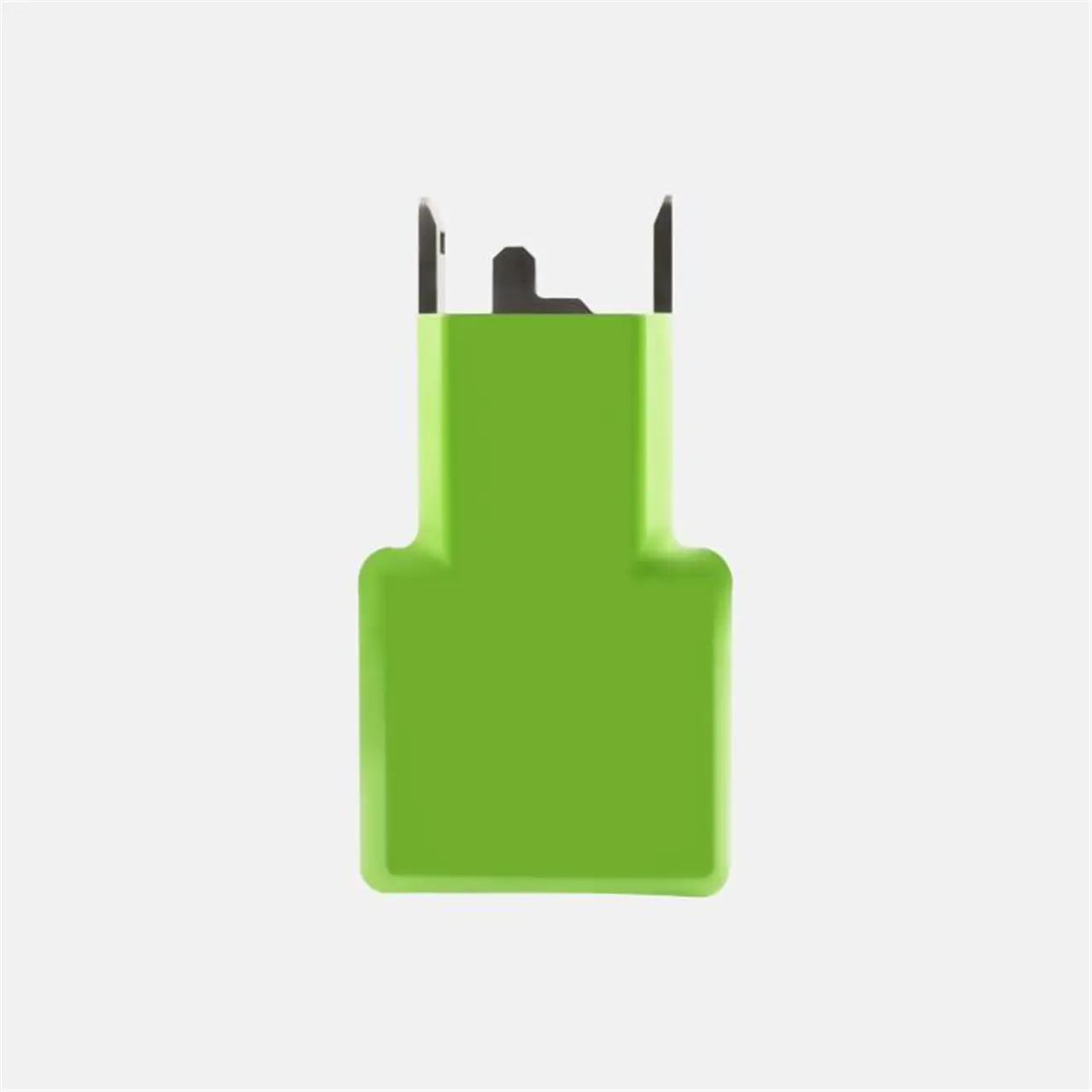

Cardiac Probe Clamping Upper Cover (304 Stainless Steel)

Project Overview

This cardiac probe clamping upper cover is a precision component specifically designed for medical ultrasound equipment, where it plays a critical role in securing and protecting the cardiac probe during diagnostic procedures.

Manufactured from 304 stainless steel, the component benefits from the material’s exceptional stability, corrosion resistance, and biocompatibility, making it an ideal choice for medical-grade applications. Precision machining ensures that every dimension strictly adheres to the design standard, guaranteeing perfect fitment with the ultrasound system and minimizing risks of probe displacement or instability.

The component not only ensures diagnostic accuracy by maintaining probe stability but also undergoes additional surface finishing processes, such as baking paint coating, which provide an elegant appearance while enhancing wear resistance and corrosion protection—ensuring durability under demanding hospital conditions.

Manufacturing Challenges

Medical-Grade Precision

Even slight dimensional deviations can affect probe stability and diagnostic accuracy.

Material Processing

304 stainless steel requires strict control of machining parameters to prevent deformation, surface scratches, or burr formation.

Surface Quality Requirements

The final product must not only meet functional performance but also achieve aesthetic and hygienic standards suitable for medical environments.

Quality Assurance

Every cardiac probe clamping cover undergoes strict inspection, including:

Dimensional Accuracy Check – verifying compliance with medical device design standards

Surface Integrity Inspection – ensuring no burrs, scratches, or defects remain

Corrosion Resistance Testing – validating durability of the stainless steel and coating

Assembly Fitment Verification – guaranteeing secure integration with ultrasound devices

Our Solutions

Precision CNC Machining

Multi-axis CNC machining ensures dimensional accuracy across all features, maintaining tight tolerances critical to probe stability.

Surface Finishing

Advanced polishing and baking paint coating provide both aesthetic appeal and enhanced protection against wear and corrosion.

Stringent Process Control

Each stage of machining and finishing is monitored to ensure the final product meets medical-grade reliability and cleanliness requirements.

Application Value

Medical Ultrasound Systems – ensuring probe stability for accurate cardiac imaging.

Diagnostic Reliability – minimizing errors caused by probe movement or misalignment.

Durability & Aesthetics – corrosion-resistant, wear-resistant, and visually suitable for modern medical environments.

Company Profile

14+

years

Kansd was established in 2011. As an enterprise specializing in precision manufacturing and assembly, we located in Shenzhen,China. With more than 70 professional employees, Kansd has a professional technical team that has been deeply engaged in the precision manufacturing industry for more than ten years.

- One-stop service

- High quality products

- Advanced production equipment

- OEM&ODM services