Automotive Precision Parts: Case Studies on Custom Solutions from Leading Manufacturers

As a B2B purchaser, finding reliable and precision-engineered automotive parts is essential. Our **Automotive Precision Part Case Studies** demonstrate the impressive capabilities of trusted factories and manufacturers. These case studies illustrate our partnerships with clients to deliver high-quality components that enhance performance and reliability at every stage, from prototyping to mass production. With **Kansd Precision Industry Co., Ltd.** as your partner, you can expect exceptional quality and service designed to meey your specific requirements. We maintain rigorous quality control and innovative processes to distinguish ourselves in the industry, ensuring you receive precision and efficiency in every project. These case studies will showcase how we can contribute to your automotive endeavors and help you achieve your goals.Trending Automotive Precision Part Case Studies Delivers Unmatched Quality For the Current Year

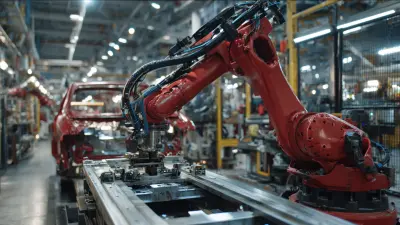

In the rapidly evolving automotive industry, precision and quality are paramount. As manufacturers seek competitive advantages, case studies showcasing trending Automotive Precision Parts have become invaluable resources. Highlighting superior craftsmanship and innovative manufacturing techniques, these case studies reveal how precision components can significantly enhance vehicle performance and reliability. By leveraging advanced technologies and skilled engineering, companies are now producing parts that not only meet but often exceed industry standards. The integration of state-of-the-art machinery, such as CNC machines and precision grinding tools, plays a critical role in achieving unmatched quality. These technologies enable manufacturers to produce complex geometries and intricate designs with exceptional accuracy. Moreover, rigorous quality control processes, involving advanced measuring instruments, ensure that each part fulfills stringent specifications. As global suppliers increasingly adopt these methodologies, they are better positioned to fulfill the growing demands of the automotive sector, providing procurement teams with the assurance of consistent quality and performance. As the industry shifts towards sustainability and efficiency, precision parts will take center stage in the development of eco-friendly vehicles and advanced automotive technologies. By staying ahead of these trends, manufacturers can not only enhance their product offerings but also contribute to a greener future. For procurement professionals looking to optimize their supply chains, investing in partners who emphasize precision manufacturing is becoming more than just an option; it's a necessity in navigating the modern automotive landscape.

Trending Automotive Precision Part Case Studies Delivers Unmatched Quality For the Current Year

| Case Study | Industry | Part Type | Materials Used | Quality Metrics | Year |

|---|---|---|---|---|---|

| Case Study A | Automotive | Engine Component | Aluminum Alloy | Tensile Strength: 400 MPa | 2023 |

| Case Study B | Automotive | Suspension Part | Carbon Steel | Fatigue Strength: 300 MPa | 2023 |

| Case Study C | Automotive | Transmission Housing | Titanium Alloy | Corrosion Resistance: >1000 hrs | 2023 |

| Case Study D | Automotive | Brake Rotor | Cast Iron | Thermal Conductivity: 50 W/m·K | 2023 |

| Case Study E | Automotive | Fuel Injector | Stainless Steel | Leak Rate: | 2023 |

Advantages Explained Automotive Precision Part Case Studies Stands Out Guarantees Peak Performance

J

James Wilson

Excellent quality overall. The after-sales service was efficient, with knowledgeable representatives who guided me well.

22 June 2025

O

Oliver Scott

Excellent quality! The after-sales support was professional, ensuring I was informed and satisfied.

16 June 2025

L

Liam King

Extremely satisfied with the product! The after-sales team was responsive and knowledgeable, providing great assistance.

18 June 2025

O

Oliver Perez

Quality and professionalism at its best! The support team answered all my questions swiftly.

01 July 2025

O

Oliver King

Great quality product! The after-sales service team was knowledgeable and catered to all my needs efficiently.

06 June 2025

L

Lily Martinez

This product is phenomenal! The quality is evident, and the after-sales team was brilliant in their support.

24 May 2025