Custom Automotive Precision Machining by Top Manufacturers & Factories for Quality Parts

When it comes to **Automotive Precision Machining**, partnering with top suppliers and manufacturers that uphold high-quality standards is essential. My extensive experience in the industry highlights that precision is crucial for enhancing performance and safety in automotive applications. At Kansd Precision Industry Co., Ltd., we deliver exceptional precision machined components designed to meet your specific requirements. Our unwavering commitment to quality craftsmanship ensures that you receive parts that exceed expectations. We prioritize quality control throughout the manufacturing process, guaranteeing that every product undergoes stringent testing. With our unmatched precision and expertise, your automotive projects can reach new heights. Let's collaborate to bring your automotive innovations to life!Practical Methods To Automotive Precision Machining More Than a Supplier - A Partner Where Service Meets Innovation

In today's highly competitive automotive industry, precision machining is no longer just about producing parts; it's about forging strong partnerships that drive innovation and efficiency. Organizations seeking reliable suppliers often underestimate the value of a collaborative approach, where suppliers act not just as vendors, but as essential partners in the manufacturing process. This partnership model offers a unique blend of service and innovation, enhancing product quality, reducing lead times, and ultimately boosting the bottom line. A key aspect of this partnership is technological proficiency. With advanced equipment such as CNC machines, lathes, and grinding machines, businesses can ensure high precision and fine tolerances in every component produced. By integrating state-of-the-art measuring instruments like CMM and 2D imaging, manufacturers can uphold stringent quality standards and conduct thorough inspections throughout the production process. This level of commitment to precision not only ensures reliability but also positions partners as leaders in technological innovation, capable of addressing the evolving needs of the automotive sector. Moreover, strategic collaboration facilitates a seamless flow of ideas and feedback between partners, fostering continuous improvement and adaptation to market demands. When suppliers see themselves as partners, they are more likely to invest in developing tailored solutions that align with their clients' strategic goals. This agile approach not only alleviates supply chain risks but also positions automotive companies to embrace new technological advancements swiftly, ensuring they remain competitive in a fast-paced industry. By focusing on building partnerships rather than just transactional relationships, businesses can create a sustainable model of growth founded on mutual success and innovation.

Practical Methods To Automotive Precision Machining More Than a Supplier - A Partner Where Service Meets Innovation

| Method | Description | Benefits | Application Area |

|---|---|---|---|

| CNC Machining | Computer Numerical Control machining employs automation for precise measurements and operations. | High precision, reduced human error, and the capability to produce complex shapes. | Engine components, transmission parts, and complex assemblies. |

| 5-Axis Machining | Machining that moves in five different axes for intricate designs and shapes. | Increased efficiency and the ability to create complex geometries. | Aerospace parts, automotive molds, and complex fittings. |

| Laser Cutting | Uses a high-powered laser to cut materials with precision. | Clean cuts, minimal waste, and high repeatability. | Body panels, brackets, and intricate designs. |

| Additive Manufacturing | A process that builds components by adding material layer by layer. | Design flexibility and reduced material waste. | Prototype development and custom components. |

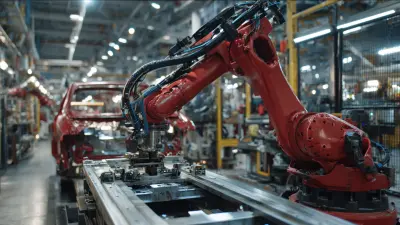

| Robotic Automation | Integrating robotic systems for repetitive and precise tasks in machining. | Increased output and consistency in production processes. | Production lines, assembly operations, and repetitive machining tasks. |

Uncovering Automotive Precision Machining Winning in 2025 Your End-to-End Solution

R

Rachel Adams

This product has significantly improved our workflow. The professionalism of the support staff really made a difference in our experience.

14 June 2025

E

Emma Reed

The product quality is fantastic. The after-sales service was impressive, with knowledgeable staff always ready to help.

17 May 2025

S

Sophia Nelson

Great product quality! The after-sales service was second to none, with a staff that truly cares.

01 July 2025

H

Harper Flores

Incredible quality from start to finish. The professionalism of the after-sales team is commendable!

22 June 2025

S

Sofia Roberts

What an excellent purchase! The product quality is incredible, and the follow-up support was stellar.

10 May 2025

S

Sophia Martinez

What a great experience! The product is excellent, and the customer service team was professional and supportive.

12 June 2025