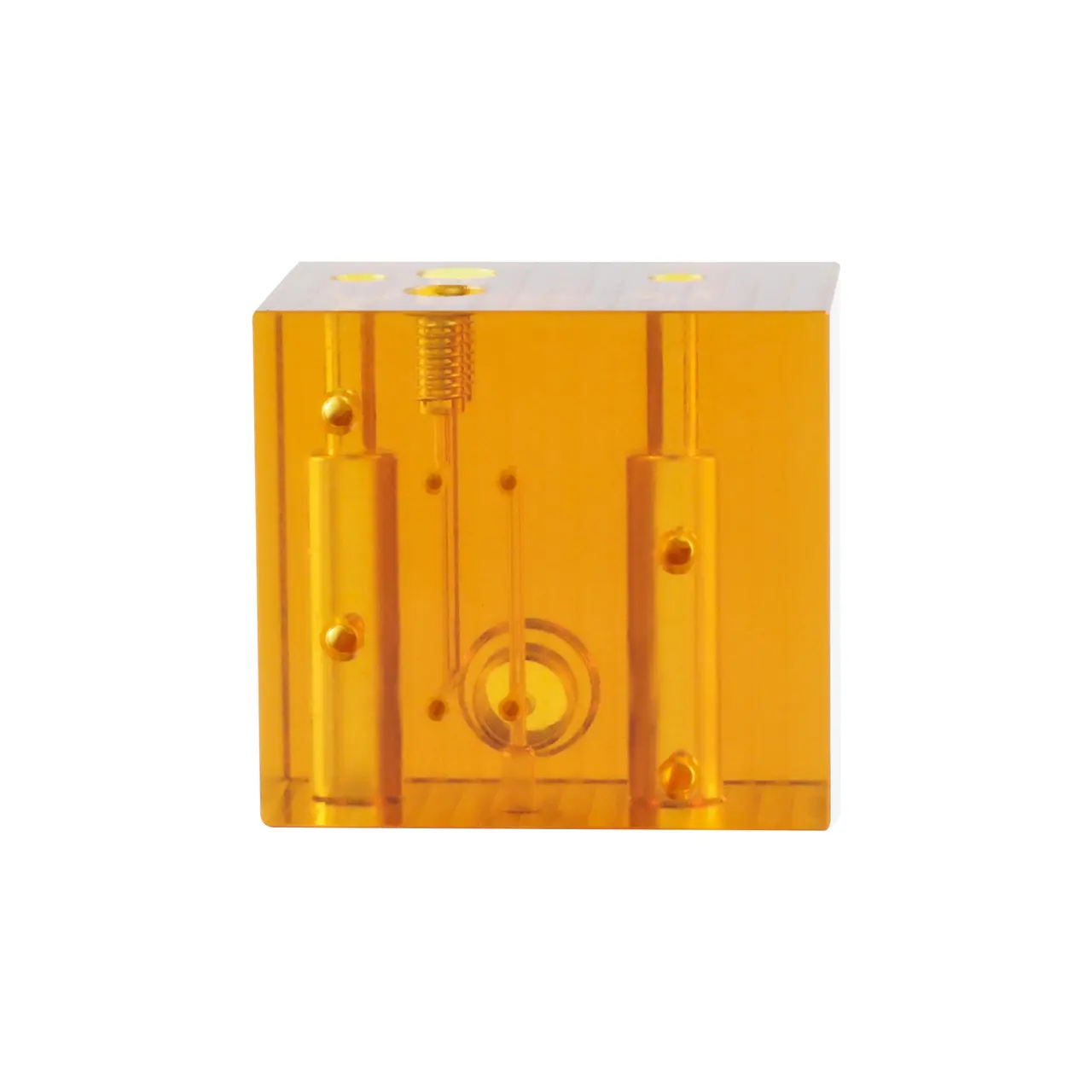

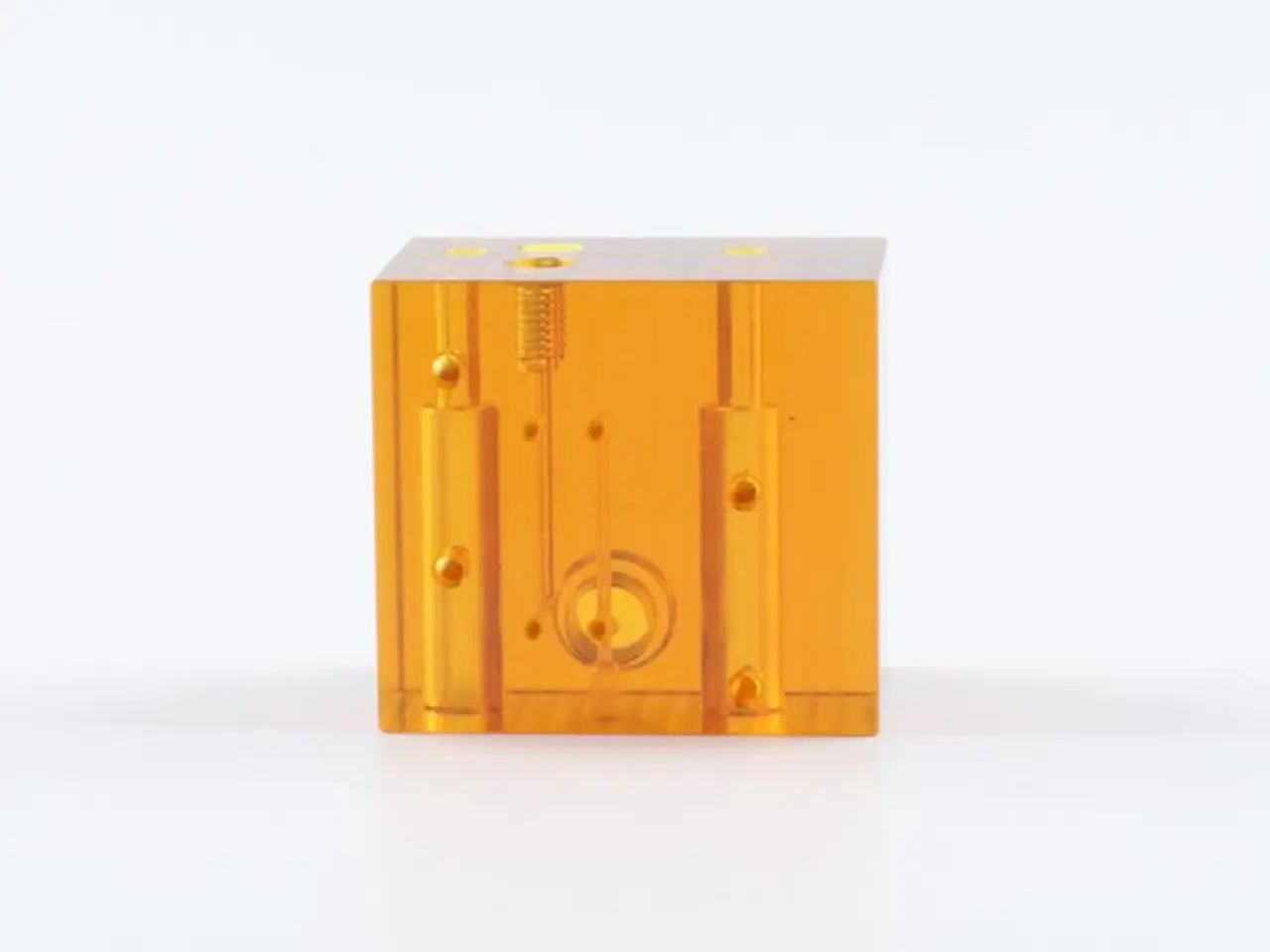

Adapter Integration Block (PEI Engineering Plastic)

Product Overview

The adapter integration block is a precision fluid component manufactured from PEI (Polyetherimide), a high-performance engineering plastic renowned for its high strength, thermal resistance, and optical transparency. These properties make PEI an ideal choice for demanding applications, particularly in fluid control systems where both mechanical stability and visibility are critical.

The block features an external size of 32 × 35 × 23 mm with a regular rectangular profile, designed for easy installation and seamless integration into complex equipment assemblies. Distributed across multiple faces are Ø1 mm micro-holes with depths up to 28 mm, which play an essential role in fluid transmission.

To ensure functionality and reliability, hole wall smoothness is strictly controlled, and burrs at connections and threaded sections are completely eliminated to prevent any obstruction to fluid flow. Furthermore, the external surface must remain free of machining marks or tool lines—not only for aesthetic reasons but also to allow clear observation of internal fluid movement where transparency is required.

Manufacturing Challenges

Micro-Hole Machining

Drilling Ø1 mm holes up to 28 mm deep while maintaining smooth walls.

Burr-Free Connections

Ensuring no residual burrs in connecting passages or threaded sections.

Surface Finish Without Polishing

Achieving tool-mark-free surfaces solely through optimized machining, without additional polishing.

Our Solutions

High-Precision Micro-Drilling

Advanced drilling technology ensures consistent hole geometry and wall smoothness.

Burr-Free Processing

Special cutting strategies eliminate micro-burrs in through-holes and threaded sections.

Optimized Tooling & Parameters

Cutting tools and machining parameters are precisely tuned to avoid tool marks and ensure clean surfaces.

Quality Assurance

Every adapter block is subject to:

Hole Geometry & Depth Verification – confirming Ø1 mm holes reach 28 mm depth with accuracy.

Surface Integrity Check – ensuring no tool marks, scratches, or defects.

Burr-Free Validation – guaranteeing smooth fluid passages without obstruction.

Application Value

Fluid Transmission Systems – precise, obstruction-free flow pathways.

Medical & Analytical Equipment – optical transparency allows monitoring of fluid dynamics.

High-Performance Industrial Components – withstands heat, stress, and chemical exposure.

Company Profile

14+

years

Kansd was established in 2011. As an enterprise specializing in precision manufacturing and assembly, we located in Shenzhen,China. With more than 70 professional employees, Kansd has a professional technical team that has been deeply engaged in the precision manufacturing industry for more than ten years.

- One-stop service

- High quality products

- Advanced production equipment

- OEM&ODM services