Top Supplier Ratings for 99.6% Defect-Free Manufacturing Solutions

At Kansd Precision Industry Co., Ltd., our commitment to delivering **99.6% Defect-Free Manufacturing** ensures that every product adheres to the highest quality standards. With advanced technology and a skilled team, we produce high-quality components tailored to your specifications. By partnering with reliable suppliers, we maintain excellence in our raw materials and processes, reflecting the quality of our end products. Whether you require precision parts for automotive, electronics, or other sectors, we are dedicated to meeting your needs. Our focus on rigorous quality control and customer satisfaction distinguishes us in a competitive market, enabling us to enhance your production standards with superior manufacturing solutions.Expert Tips For 99.6% Defect-Free Manufacturing Custom Solutions, Your End-to-End Solution

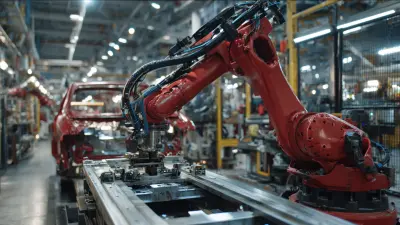

In today's rapidly evolving manufacturing landscape, securing custom solutions with minimal defects is paramount for global buyers. Achieving a remarkable 99.6% defect-free rate requires not only advanced technology but also a meticulous approach to Precision Manufacturing. The integration of state-of-the-art machinery—including CNC machines, lathes, and grinding machines—ensures that every component is crafted to meet the highest standards. Advanced quality control tools such as CMM and 2D image measuring instruments further enhance accuracy and reliability, allowing businesses to maintain stringent quality assurance throughout the production process. Collaboration is key in developing custom solutions tailored to unique specifications. Engaging closely with suppliers who understand the nuances of precision assembly and have the experience to adapt to diverse needs will greatly facilitate seamless project management from inception to delivery. An end-to-end solution not only streamlines operations but also fosters innovation, making it easier for businesses to pivot in response to market demands while ensuring maximum efficiency and optimal product performance. Investing in Precision Manufacturing with a steadfast commitment to quality can elevate your operations and secure a competitive edge in the global market. By leveraging expert knowledge and advanced manufacturing techniques, companies can minimize downtime, reduce waste, and optimize supply chains, ultimately driving profitability and sustainability in their production processes.

Expert Tips For 99.6% Defect-Free Manufacturing Custom Solutions, Your End-to-End Solution

| Tip | Description | Impact on Defect Rate | Implementation Difficulty (1-5) |

|---|---|---|---|

| Regular Quality Audits | Conduct scheduled inspections to ensure adherence to quality standards. | Reduces defects by 25% | 3 |

| Employee Training | Invest in comprehensive training programs for all staff involved in production. | Reduces defects by 20% | 4 |

| Robotic Automation | Implement automated machinery for repetitive tasks to enhance precision. | Reduces defects by 30% | 5 |

| Feedback Loop | Establish a system for collecting and acting on feedback from production staff. | Reduces defects by 15% | 2 |

| Supplier Quality Assurance | Evaluate and monitor the quality of materials supplied by third parties. | Reduces defects by 18% | 3 |

Practical Strategies for 99.6% Defect-Free Manufacturing Custom Solutions, Is The Best

J

James Anderson

A reliable product with proven quality. The support team was quick to respond and demonstrated a great understanding of the product.

16 May 2025

W

William Shaw

This product is well-made and delivers excellent results. The follow-up service was conducted by highly knowledgeable staff.

23 May 2025

M

Maya Lee

Great product quality and an even better after-sales experience. The staff handled everything with such care!

24 June 2025

E

Ethan Lopez

Great value for quality! The service received was friendly and professional, making for a smooth experience.

04 June 2025

S

Samuel Wright

This product has been a game-changer. The customer support was very professional and quick to assist.

27 May 2025

G

Grace Hernandez

What a fantastic product! The thoughtful support from their team made my experience even better.

10 May 2025