Precision Machining at 0.002mm: Custom Solutions from Reliable Suppliers & Factories

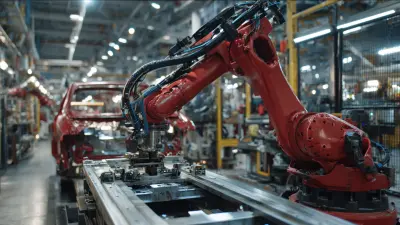

When precision is crucial, our 0.002mm Precision Machining service is the optimal choice for discerning clients. With cutting-edge technology and a skilled team, we specialize in meeting your custom machining requirements. Our facilities are engineered for superior quality and consistent performance, ensuring that every component adheres to your precise specifications. Serving industries such as aerospace, automotive, and medical, we recognize the essential role of precision in your projects.Why Professionals Prefer 0.002mm Precision Machining Ahead of the Curve Leads the Global Market

Precision machining has become an essential aspect of modern manufacturing, especially for professionals aiming to maintain a competitive edge in the global market. With the increasing demand for high-quality components across various industries, the 0.002mm Precision Machining standard has emerged as a leading choice. This level of precision not only enhances product performance but also contributes to significant cost savings by minimizing waste and reducing the need for extensive post-processing. The advanced capabilities of CNC machines, lathes, milling machines, and grinding machines enable manufacturers to produce intricate designs and complex geometries with remarkable accuracy. The integration of medium-speed wire cutting machines along with coordinate measuring machines (CMM) ensures that every piece meets stringent quality control measures. As a result, businesses can rely on consistent precision, allowing them to innovate and adapt to market needs swiftly. In an era where precision and reliability are paramount, businesses that embrace 0.002mm Precision Machining are better positioned to meet the demands of discerning global clients. By investing in state-of-the-art technology and skilled expertise, companies can lead their industries while securing long-term partnerships and expanding their market reach. Prospective buyers are encouraged to consider these advantages when seeking suppliers capable of delivering top-tier precision components.

Why Professionals Prefer 0.002mm Precision Machining Ahead of the Curve Leads the Global Market

| Parameter | Details | Impact on Industry |

|---|---|---|

| Precision Level | 0.002mm | Increased accuracy of manufactured parts |

| Market Demand | High | Driving investment and innovation |

| Applications | Aerospace, Medical, Automotive | Essential for safety and reliability |

| Material Types | Aluminum, Titanium, Stainless Steel | Diverse capabilities in machining |

| Technological Advancements | CNC Machining, 3D Printing | Enhanced precision and efficiency |

| Challenges | Cost, Technology Integration | Balancing quality and cost-effectiveness |

Curated Selection of 0.002mm Precision Machining Products Dominates

S

Sofia Robinson

An amazing product with great attention to quality. The after-sales support was equally impressive from start to finish.

25 June 2025

S

Sam Patel

Very pleased with the quality! The staff handled my inquiries with professionalism and expertise.

06 July 2025

E

Emma Reed

The product quality is fantastic. The after-sales service was impressive, with knowledgeable staff always ready to help.

17 May 2025

V

Victoria Edwards

The quality is outstanding. The after-sales team was professional, making my experience a pleasure.

03 July 2025

M

Michael Allen

Excellent quality! The after-sales service was prompt, with an incredibly knowledgeable team.

01 July 2025

L

Liam Nelson

Very happy with this purchase! The craftsmanship is impressive, and the after-sales service was exemplary.

04 June 2025